Page 28 - Failure Analysis Case Studies II

P. 28

15

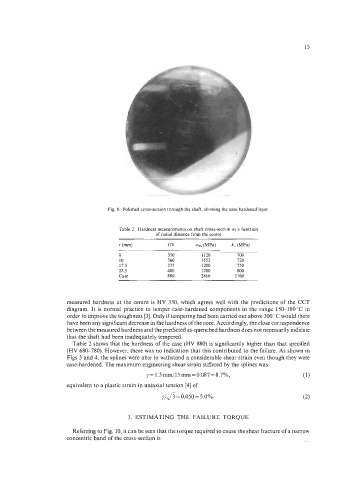

Fig. 8. Polished cross-section through the shaft, showing the case-hardened layer

Table 2. Hardness measurements on shaft cross-section as a function

of radial distance from the centre

r (mm) HV ~TS (MW k, (MPa)

0 350 1120 700

10 360 1152 720

17.5 375 1200 750

22.5 400 1280 800

Case 880 2816 1760

measured hardness at the centre is HV 350, which agrees well with the predictions of the CCT

diagram. It is normal practice to temper case-hardened components in the range 15G18O"C in

order to improve the toughness [3]. Only if tempering had been carried out above 300 "C would there

have been any significant decrease in the hardness of the core. Accordingly, the close correspondence

between the measured hardness and the predicted as-quenched hardness does not necessarily indicate

that the shaft had been inadequately tempered.

Table 2 shows that the hardness of the case (HV 880) is significantly higher than that specified

(HV 68G780). However, there was no indication that this contributed to the failure. As shown in

Figs 3 and 4, the splines were able to withstand a considerable shear strain even though they were

case-hardened. The maximum engineering shear strain suffered by the splines was

y = 1.3 mm/l5 mm = 0.087 = 8.7%, (1)

equivalent to a plastic strain in uniaxial tension [4] of

3. ESTIMATING THE FAILURE TORQUE

Referring to Fig. 10, it can be seen that the torque required to cause the shear fracture of a narrow

concentric band of the cross-section is