Page 25 - Failure Analysis Case Studies II

P. 25

12

I

.-c

F

I

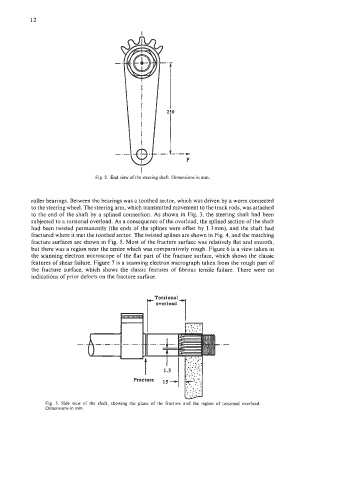

Fig. 2. End view of the steering shaft. Dimensions in mm.

roller bearings. Between the bearings was a toothed sector, which was driven by a worm connected

to the steering wheel. The steering arm, which transmitted movement to the track rods, was attached

to the end of the shaft by a splined connection. As shown in Fig. 3, the steering shaft had been

subjected to a torsional overload. As a consequence of the overload, the splined section of the shaft

had been twisted permanently (the ends of the splines were offset by 1.3mm), and the shaft had

fractured where it met the toothed sector. The twisted splines are shown in Fig. 4, and the matching

fracture surfaces are shown in Fig. 5. Most of the fracture surface was relatively flat and smooth,

but there was a region near the centre which was comparatively rough. Figure 6 is a view taken in

the scanning electron microscope of the flat part of the fracture surface, which shows the classic

features of shear failure. Figure 7 is a scanning electron micrograph taken from the rough part of

the fracture surface, which shows the classic features of fibrous tensile failure. There were no

indications of prior defects on the fracture surface.

171

..._ .

t

..-

' : I

Fracture

Fig. 3. Side view of the shaft, showing the plane of the fracture and the region of torsional overload.

Dimensions in mm.