Page 389 - Failure Analysis Case Studies II

P. 389

374

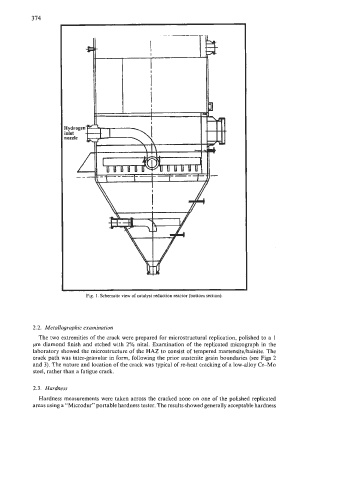

Fig. 1. Schematic view of catalyst reduction reactor (bottom section).

2.2. Metallographic examination

The two extremities of the crack were prepared for microstructural replication, polished to a 1

pm diamond finish and etched with 2% nital. Examination of the replicated micrograph in the

laboratory showed the microstructure of the HAZ to consist of tempered martensite/bainite. The

crack path was inter-granular in form, following the prior austenite grain boundaries (see Figs 2

and 3). The nature and location of the crack was typical of re-heat cracking of a low-alloy Cr-Mo

steel, rather than a fatigue crack.

2.3. Hardness

Hardness measurements were taken across the cracked zone on one of the polished replicated

areas using a “Microdur” portable hardness tester. The results showed generally acceptable hardness