Page 384 - Failure Analysis Case Studies II

P. 384

3 69

Table 3. Mechanical properties of the pins

0.2% yield Ultimate tensile Impact energy at

strength strength Elongation room temperature

Pin (MP4 (MPa) W) (J)

N2 1 I82 1439 23.2 -

N3 1 I82 1458 21.6 -

N4 1162 1579 24.8 -

N5 - - - 22

N6 - - - 57

N7 - - - 23

N8 - - ~ 24

N9 - - - 45

Average 1175 1492 23.2 34

Standard deviation 11.5 76 1.6 16

'En 51" 635 8 50-1 000 - -

AISI 431' - 1210-1515 - -

AISI 4313 1030 1370 16 -

AISI 4314 1080 1360 23 -

' British standard specification BS 970 (950-1O2O0C, oil quenched and tempered at 550-650"C).

*980-1065"C, oil quenched and tempered at 230-370°C [3].

' Quenched and tempered at 260°C (Alloy Digest).

Quenched and tempered at 427°C (Alloy Digest).

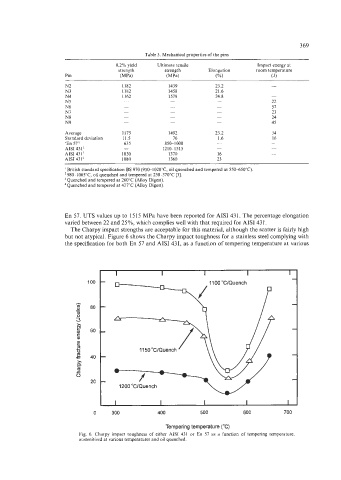

En 57. UTS values up to 1515 MPa have been reported for AIS1 431. The percentage elongation

varied between 22 and 25%, which complies well with that required for AIS1 431.

The Charpy impact strengths are acceptable for this material, although the scatter is fairly high

but not atypical. Figure 6 shows the Charpy impact toughness for a stainless steel complying with

the specification for both En 57 and AIS1 431, as a function of tempering temperature at various

1 I I I I -

80 -

60 -

40 - 1150 "CIQuench

20 -

1200 "CIQuench

0 300 400 500 600 700

Tempering temperature ("C)

Fig. 6. Charpy impact toughness of either AISI 431 or En 57 as a function of tempering temperature,

austenitized at various temperatures and oil quenched.