Page 383 - Failure Analysis Case Studies II

P. 383

368

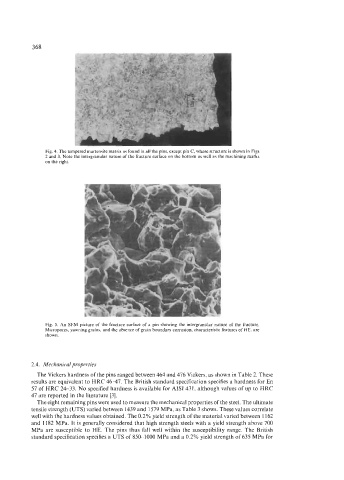

Fig. 4. The tempered martensite matrix as found in all the pins, except pin C, whose structure is shown in Figs

2 and 3. Note the intergranular nature of the fracture surface on the bottom as well as the machining marks

on the right.

Fig. 5. An SEM picture of the fracture surface of a pin showing the intergranular nature of the fracture.

Micropores, yawning grains, and the absence of grain boundary corrosion, characteristic features of HE, are

shown.

2.4. Mechanicalproperties

The Vickers hardness of the pins ranged between 464 and 476 Vickers, as shown in Table 2. These

results are equivalent to HRC 46-47. The British standard specification specifies a hardness for En

57 of HRC 24-33. No specified hardness is available for AIS1 431, although values of up to HRC

47 are reported in the literature [3].

The eight remaining pins were used to measure the mechanical properties of the steel. The ultimate

tensile strength (UTS) varied between 1439 and 1579 MPa, as Table 3 shows. These values correlate

well with the hardness values obtained. The 0.2% yield strength of the material varied between 1162

and 1182 MPa. It is generally considered that high strength steels with a yield strength above 700

MPa are susceptible to HE. The pins thus fall well within the susceptibility range. The British

standard specification specifies a UTS of 85Ck-1000 MPa and a 0.2% yield strength of 635 MPa for