Page 57 - Failure Analysis Case Studies II

P. 57

42

- 8.0

- 6.0

- 4.0

Dune Sand BackfN

- 2.0

- 0.0

17.5 4

unit

weight cohesion

~/m3

18.5

16.0

20.0

I Clay Back Fill

___ ~ ~~

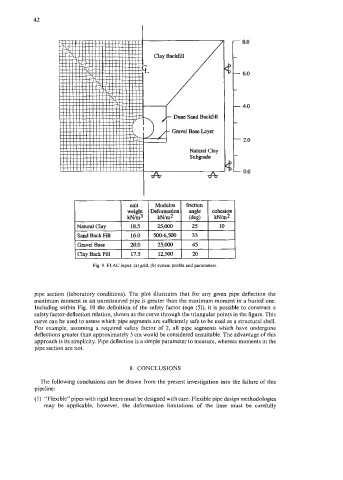

Fig. 9. FLAC input: (a) grid, (b) system profile and parameters.

pipe section (laboratory conditions). The plot illustrates that for any given pipe deflection the

maximum moment in an unrestrained pipe is greater than the maximum moment in a buried one.

Including within Fig. 10 the definition of the safety factor (eqn (5)), it is possible to construct a

safety factor-deflection relation, shown as the curve through the triangular points in the figure. This

curve can be used to assess which pipe segments are sufficiently safe to be used as a structural shell.

For example, assuming a required safety factor of 2, all pipe segments which have undergone

deflections greater than approximately 5 cm would be considered unsuitable. The advantage of this

approach is its simplicity. Pipe deflection is a simple parameter to measure, whereas moments in the

pipe section are not.

8. CONCLUSIONS

The following conclusions can be drawn from the present investigation into the failure of this

pipeline:

(1) ‘‘Flexible” pipes with rigid liners must be designed with care. Flexible pipe design methodologies

may be applicable, however, the deformation limitations of the liner must be carefully