Page 214 - Fiber Fracture

P. 214

STRENGTH AND Fh'ACTLIRE OF METALLIC FILAMENTS 199

0 40 80 120 rw1

Notchdepth --3

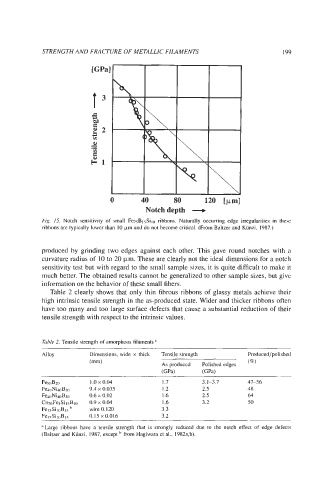

Fig. 15. Notch sensitivity of small Fe7~BlsSilo ribbons. Naturally occumng edge irregularities in these

ribbons are typically lower than IO wm and do not become critical. (From Baltzer and Kunzi, 1987.)

produced by grinding two edges against each other. This gave round notches with a

curvature radius of 10 to 20 pm. These are clearly not the ideal dimensions for a notch

sensitivity test but with regard to the small sample sizes, it is quite difficult to make it

much better. The obtained results cannot be generalized to other sample sizes, but give

information on the behavior of these small fibers.

Table 2 clearly shows that only thin fibrous ribbons of glassy metals achieve their

high intrinsic tensile strength in the as-produced state. Wider and thicker ribbons often

have too many and too large surface defects that cause a substantial reduction of their

tensile strength with respect to the intrinsic values.

Table 2. Tensile strength of amorphous filaments a

Alloy Dimensions, wide x thick Tensile strength Produced/polished

(mm)

As produccd Polished edges (%)

(GW GPa)

Fed20 1 .o x 0.04 1.7 3.1-3.7 47-56

Fedi~B21) 9.4 x 0.035 I .2 2.5 48

Fedi4oB20 0.6 x 0.02 1.6 2.5 64

Co7oFesSil~Blo 0.9 x 0.04 I .6 3.2 50

FeaSiloB1S wire 0.120 3.3

Fedi IOB IS 0.15 x0.016 3.2

"Large ribbons have a tensile strength that is strongly reduced due to the notch effect of edge defects

(Baker and Kunii, 1987, except from Hagiwara et al., 1982a,b).