Page 210 - Fiber Fracture

P. 210

STRENGTH AND FRACTURE OF METALLIC FILAMENTS 195

0 100 200 300 [GPal

Young’s modulus

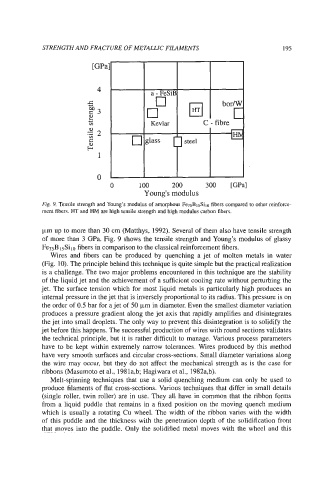

Fig. 9. Tensile strength and Young’s modulus of amorphous Fe7sBlsSilo fibers compared to other reinforce-

ment fibers. HT and HM are high tensile strength and high modulus carbon fibers.

km up to more than 30 cm (Matthys, 1992). Several of them also have tensile strength

of more than 3 GPa. Fig. 9 shows the tensile strength and Young’s modulus of glassy

Fe75B ,sSilO fibers in comparison to the classical reinforcement fibers.

Wires and fibers can be produced by quenching a jet of molten metals in water

(Fig. 10). The principle behind this technique is quite simple but the practical realization

is a challenge. The two major problems encountered in this technique are the stability

of the liquid jet and the achievement of a sufficient cooling rate without perturbing the

jet. The surface tension which for most liquid metals is particularly high produces an

internal pressure in the jet that is inversely proportional to its radius. This pressure is on

the order of 0.5 bar for a jet of 50 km in diameter. Even the smallest diameter variation

produces a pressure gradient along the jet axis that rapidly amplifies and disintegrates

the jet into small droplets. The only way to prevent this disintegration is to solidify the

jet before this happens. The successful production of wires with round sections validates

the technical principle, but it is rather difficult to manage. Various process parameters

have to be kept within extremely narrow tolerances. Wires produced by this method

have very smooth surfaces and circular cross-sections. Small diameter variations along

the wire may occur, but they do not affect the mechanical strength as is the case for

ribbons (Masumoto et al., 1981a,b; Hagiwara et al., 1982a,b).

Melt-spinning techniques that use a solid quenching medium can only be used to

produce filaments of flat cross-sections. Various techniques that differ in small details

(single roller, twin roller) are in use. They all have in common that the ribbon forms

from a liquid puddle that remains in a fixed position on the moving quench medium

which is usually a rotating Cu wheel. The width of the ribbon varies with the width

of this puddle and the thickness with the penetration depth of the solidification front

that moves into the puddle. Only the solidified metal moves with the wheel and this