Page 213 - Fiber Fracture

P. 213

198 H.U. Kiinzi

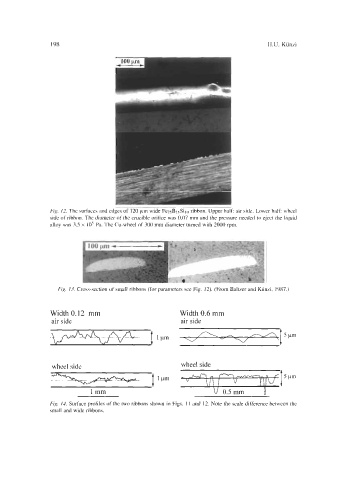

Fig. 12. The surfaces and edges of 120 Iirn wide Fe75B15Sil0 ribbon. Upper half air side. Lower half wheel

side of ribbon. The diameter of the crucible orifice was 0.07 mm and the pressure needed to eject the liquid

alloy was 3.5 x lo5 Pa. The Cu-wheel of 300 mm diameter turned with 2000 rpm.

Fig. 13. Cross-section of small ribbons (for parameters see Fig. 12). (From Baltzer and Kunzi, 1987.)

Width 0.12 mm Width 0.6 mm

air side air side

wheel side wheel side

1 1 om .- ,-vm~ \I nuF

v

I

1 mm v 0.5 mm I/

Fig. 14. Surface profiles of the two ribbons shown in Figs. I I and 12. Note the scale difference between the

small and wide ribbons.