Page 302 - Fiber Fracture

P. 302

284 J.W.S. Hearle

Force

Po

h

D, Amplitude, y

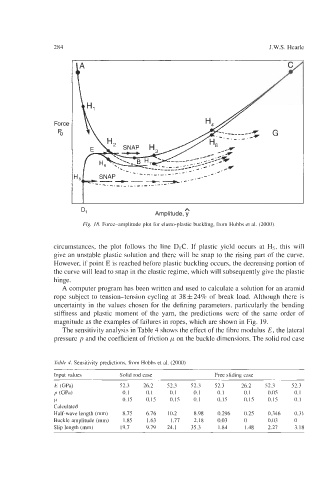

Fig. 18. Force-amplitude plot for elasto-plastic buckling, from Hobbs et al. (2000).

circumstances, the plot follows the line DIC. If plastic yield occurs at Hg, this will

give an unstable plastic solution and there will be snap to the rising part of the curve.

However, if point E is reached before plastic buckling occurs, the decreasing portion of

the curve will lead to snap in the elastic regime, which will subsequently give the plastic

hinge.

A computer program has been written and used to calculate a solution for an aramid

rope subject to tension-tension cycling at 38f24% of break load. Although there is

uncertainty in the values chosen for the defining parameters, particularly the bending

stiffness and plastic moment of the yarn, the predictions were of the same order of

magnitude as the examples of failures in ropes, which are shown in Fig. 19.

The sensitivity analysis in Table 4 shows the effect of the fibre modulus E, the lateral

pressure p and the coefficient of friction p on the buckle dimensions. The solid rod case

Table 4. Sensitivity predictions, from Hobbs et al. (2000)

Input values Solid rod case Free sliding case

E (GPa) 52.3 26.2 52.3 52.3 52.3 26.2 52.3 52.3

P (GPa) 0.1 0.1 0.1 0.1 0.1 0.1 0.05 0.1

w 0.15 0.15 0.15 0.1 0.15 0.15 0.15 0.1

Calculated

Half-wave length (mm) 8.75 6.76 10.2 8.98 0.296 0.25 0.346 0.31

Buckle amplitude (mm) 1.85 1.63 1.77 2.18 0.03 0 0.03 0

Slip length (mm) 19.7 9.79 24.1 35.3 1.84 1.48 2.21 3.18