Page 301 - Fiber Fracture

P. 301

FRACTURE OF HIGHLY ORIENTED, CHAIN-EXTENDED POLYMER FIBRES 283

(b)

Axial force

distribution

Fig. 16. Slip lengths and force distribution, from Hobbs et al. (2000).

I

I

- LP iv Mode 4

I

k

I 4 4

0.608Lp I

4 m

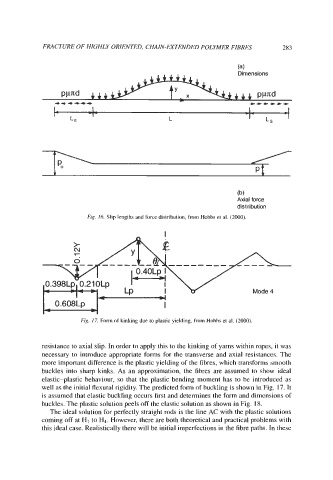

Fig. 17. Form of kinking due to plastic yielding, from Hobbs et al. (2000).

resistance to axial slip. In order to apply this to the kinking of yams within ropes, it was

necessary to introduce appropriate forms for the transverse and axial resistances. The

more important difference is the plastic yielding of the fibres, which transforms smooth

buckles into sharp kinks. As an approximation, the fibres are assumed to show ideal

elastic-plastic behaviour, so that the plastic bending moment has to be introduced as

well as the initial flexural rigidity. The predicted form of buckling is shown in Fig. 17. It

is assumed that elastic buckling occurs first and determines the form and dimensions of

buckles. The plastic solution peels off the elastic solution as shown in Fig. 18.

The ideal solution for perfectly straight rods is the line AC with the plastic solutions

coming off at HI to &. However, there are both theoretical and practical problems with

this ideal case. Realistically there will be initial imperfections in the fibre paths. In these