Page 296 - Fiber Fracture

P. 296

278 J.W.S. Hearle

Table 2. Sources of shear stresses.

Source of shear stress Observed effect

Fibres in tension: defects

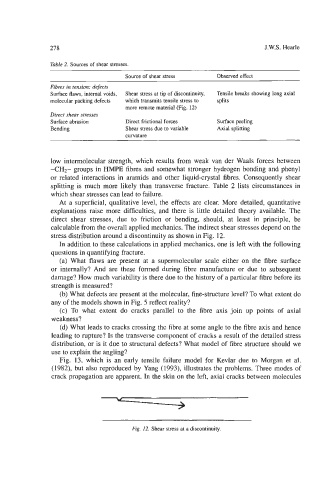

Surface flaws, internal voids, Shear stress at tip of discontinuity, Tensile breaks showing long axial

molecular packing defects which transmits tensile stress to splits

more remote material (Fig. 12)

Direct shear stresses

Surface abrasion Direct frictional forces Surface peeling

Bending Shear stress due to variable Axial splitting

curvature

low intermolecular strength, which results from weak van der Waals forces between

-CH2- groups in HMPE fibres and somewhat stronger hydrogen bonding and phenyl

or related interactions in aramids and other liquid-crystal fibres. Consequently shear

splitting is much more likely than transverse fracture. Table 2 lists circumstances in

which shear stresses can lead to failure.

At a superficial, qualitative level, the effects are clear. More detailed, quantitative

explanations raise more difficulties, and there is little detailed theory available. The

direct shear stresses, due to friction or bending, should, at least in principle, be

calculable from the overall applied mechanics. The indirect shear stresses depend on the

stress distribution around a discontinuity as shown in Fig. 12.

In addition to these calculations in applied mechanics, one is left with the following

questions in quantifying fracture.

(a) What flaws are present at a supermolecular scale either on the fibre surface

or internally? And are these formed during fibre manufacture or due to subsequent

damage? How much variability is there due to the history of a particular fibre before its

strength is measured?

(b) What defects are present at the molecular, fine-structure level? To what extent do

any of the models shown in Fig. 5 reflect reality?

(c) To what extent do cracks parallel to the fibre axis join up points of axial

weakness?

(d) What leads to cracks crossing the fibre at some angle to the fibre axis and hence

leading to rupture? Is the transverse component of cracks a result of the detailed stress

distribution, or is it due to structural defects? What model of fibre structure should we

use to explain the angling?

Fig. 13, which is an early tensile failure model for Kevlar due to Morgan et al.

(1982), but also reproduced by Yang (1993), illustrates the problems. Three modes of

crack propagation are apparent. In the skin on the left, axial cracks between molecules

Fig. 12. Shear stress at a discontinuity.