Page 365 - Fiber Fracture

P. 365

FRACTURE OF COMMON TEXTILE FIBRES 347

0 10 20 30 40 50

Extension %

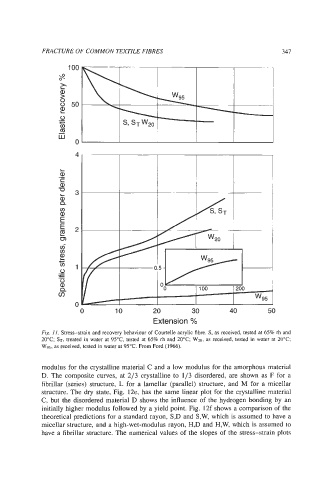

Fig 11. Stress-strain and recovery behaviour of Courtelle acrylic fibre. S, as received, tested at 65% rh and

20°C; ST, treated in water at 95"C, tested at 65% rh and 20°C; W20, as received, tested in water at 20°C:

W95. as received, tested in water at 95OC. From Ford (1966).

modulus for the crystalline material C and a low modulus for the amorphous material

D. The composite curves, at 2/3 crystalline to 1/3 disordered, are shown as F for a

fibrillar (series) structure, L for a lamellar (parallel) structure, and M for a micellar

structure. The dry state, Fig. 12e, has the same linear plot for the crystalline material

C, but the disordered material D shows the influence of the hydrogen bonding by an

initially higher modulus followed by a yield point. Fig. 12f shows a comparison of the

theoretical predictions for a standard rayon, S,D and S,W, which is assumed to have a

micellar structure, and a high-wet-modulus rayon, H,D and H,W, which is assumed to

have a fibrillar structure. The numerical values of the slopes of the stress-strain plots