Page 128 - Flexible Robotics in Medicine

P. 128

114 Chapter 5

5.2.3 Hinge design

In order to connect the different modules together, origami hinges (Fig. 5.12) with a degree-

6 vertex were used. The hinges were designed to have six valleys and two hills when bent.

When attached to the modules, these hinges allowed the device to achieve two-dimensional

(2D) bending when loose, which is desirable for insertion into the curvilinear trachea, but

only one-dimensional bending during actuation. The 2D bending when loose is essential

because it allows the device to navigate a trachea that is slightly bent out of the device’s

bending plane. The bending of the device was done by varying the inclination angles on the

modules. A 45-degree bend was achieved by using two 67.5-degree incline modules, and a

90-degree bend was achieved from two 45-degree incline modules. Changing the inclination

angles of the modules will subsequently modify the folding angles on the hinges, which

must be adjusted appropriately through measurements.

Three-dimensional (3D) designing of the hinge was done to obtain a more durable and

practical hinge. This was due to the PVC hinge being brittle and breaking after a few

bending runs. The hinge design must have a degree-6 vertex and be able to achieve six

valleys and two hills when bent. It also needs to have different folding angles depending on

the inclination angles on the modules. The final hinge model had a hole added in the center

of the degree-6 vertex. This hole added flexibility and reduced the tensile stresses, which

concentrated on the apex of the degree-6 vertex. While it was able to obtain the correct

structure of six valleys and two hills, it was still too rigid compared to the PVC hinge. Due

to current printing technology and material limitations, it was challenging to directly 3D

print a satisfactory hinge for MOJO. The PVC hinge was still the superior choice due to its

greater flexibility at the creases. However, it did have some limitations, such as its

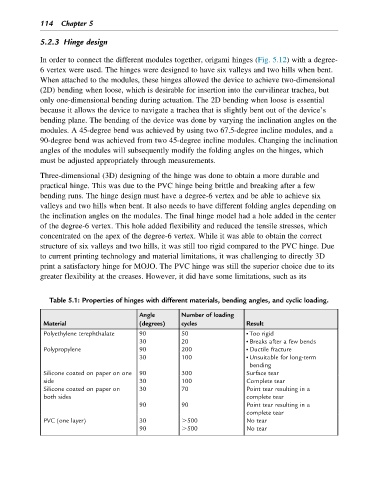

Table 5.1: Properties of hinges with different materials, bending angles, and cyclic loading.

Angle Number of loading

Material (degrees) cycles Result

Polyethylene terephthalate 90 50 Too rigid

30 20 Breaks after a few bends

Polypropylene 90 200 Ductile fracture

30 100 Unsuitable for long-term

bending

Silicone coated on paper on one 90 300 Surface tear

side 30 100 Complete tear

Silicone coated on paper on 30 70 Point tear resulting in a

both sides complete tear

90 90 Point tear resulting in a

complete tear

PVC (one layer) 30 .500 No tear

90 .500 No tear