Page 159 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 159

140 Fluid Mechanics, Thermodynamics of Turbomachinery

rotor drum and the stator blades are fixed to the outer casing. The blades upstream

of the first rotor row are inlet guide vanes. These are not considered to be a part of

the first stage and are treated separately. Their function is quite different from the

other blade rows since, by directing the flow away from the axial direction, they act

to accelerate the flow rather than diffuse it. Functionally, inlet guide vanes are the

same as turbine nozzles; they increase the kinetic energy of the flow at the expense

of the pressure energy.

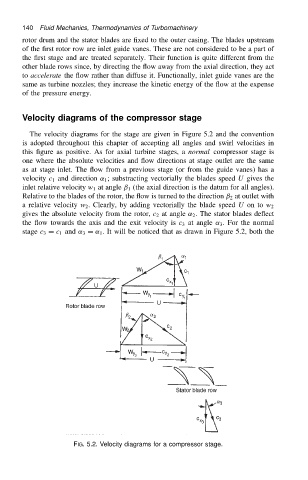

Velocity diagrams of the compressor stage

The velocity diagrams for the stage are given in Figure 5.2 and the convention

is adopted throughout this chapter of accepting all angles and swirl velocities in

this figure as positive. As for axial turbine stages, a normal compressor stage is

one where the absolute velocities and flow directions at stage outlet are the same

as at stage inlet. The flow from a previous stage (or from the guide vanes) has a

velocity c 1 and direction ˛ 1 ; substracting vectorially the blades speed U gives the

inlet relative velocity w 1 at angle ˇ 1 (the axial direction is the datum for all angles).

Relative to the blades of the rotor, the flow is turned to the direction ˇ 2 at outlet with

a relative velocity w 2 . Clearly, by adding vectorially the blade speed U on to w 2

gives the absolute velocity from the rotor, c 2 at angle ˛ 2 . The stator blades deflect

the flow towards the axis and the exit velocity is c 3 at angle ˛ 3 . For the normal

stage c 3 D c 1 and ˛ 3 D ˛ 1 . It will be noticed that as drawn in Figure 5.2, both the

FIG. 5.2. Velocity diagrams for a compressor stage.