Page 290 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 290

Radial Flow Gas Turbines 271

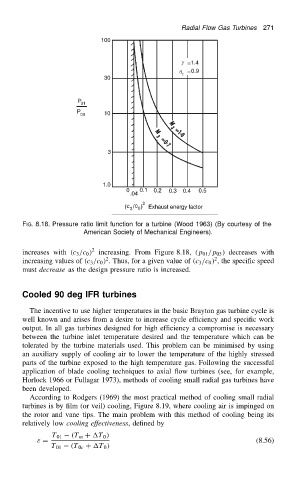

FIG. 8.18. Pressure ratio limit function for a turbine (Wood 1963) (By courtesy of the

American Society of Mechanical Engineers).

2

increases with .c 3 /c 0 / increasing. From Figure 8.18, .p 01 /p 03 / decreases with

2

2

increasing values of .c 3 /c 0 / . Thus, for a given value of .c 3 /c 0 / , the specific speed

must decrease as the design pressure ratio is increased.

Cooled 90 deg IFR turbines

The incentive to use higher temperatures in the basic Brayton gas turbine cycle is

well known and arises from a desire to increase cycle efficiency and specific work

output. In all gas turbines designed for high efficiency a compromise is necessary

between the turbine inlet temperature desired and the temperature which can be

tolerated by the turbine materials used. This problem can be minimised by using

an auxiliary supply of cooling air to lower the temperature of the highly stressed

parts of the turbine exposed to the high temperature gas. Following the successful

application of blade cooling techniques to axial flow turbines (see, for example,

Horlock 1966 or Fullagar 1973), methods of cooling small radial gas turbines have

been developed.

According to Rodgers (1969) the most practical method of cooling small radial

turbines is by film (or veil) cooling, Figure 8.19, where cooling air is impinged on

the rotor and vane tips. The main problem with this method of cooling being its

relatively low cooling effectiveness, defined by

T 01 .T m C T 0 /

ε D (8.56)

T 01 .T 0c C T 0 /