Page 63 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 63

44 Fluid Mechanics, Thermodynamics of Turbomachinery

L L

q q

R 1

W 1 Flow

Flow

1 q

1

2

2

N N

2

2N

A 2 A 2 1 + N

A R = = 1 + tan q A R = = tan q

A 1 W 1 A 1 R 1

(a) (b)

Lo

Dr 1

q i q o

r t1

N

(c)

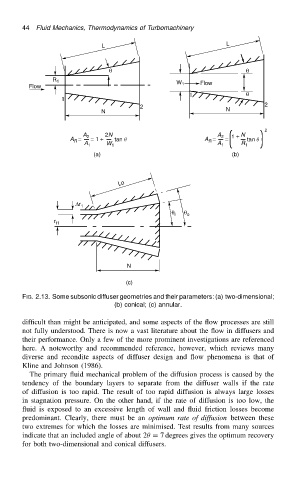

FIG. 2.13. Some subsonic diffuser geometries and their parameters: (a) two-dimensional;

(b) conical; (c) annular.

difficult than might be anticipated, and some aspects of the flow processes are still

not fully understood. There is now a vast literature about the flow in diffusers and

their performance. Only a few of the more prominent investigations are referenced

here. A noteworthy and recommended reference, however, which reviews many

diverse and recondite aspects of diffuser design and flow phenomena is that of

Kline and Johnson (1986).

The primary fluid mechanical problem of the diffusion process is caused by the

tendency of the boundary layers to separate from the diffuser walls if the rate

of diffusion is too rapid. The result of too rapid diffusion is always large losses

in stagnation pressure. On the other hand, if the rate of diffusion is too low, the

fluid is exposed to an excessive length of wall and fluid friction losses become

predominant. Clearly, there must be an optimum rate of diffusion between these

two extremes for which the losses are minimised. Test results from many sources

indicate that an included angle of about 2 D 7 degrees gives the optimum recovery

for both two-dimensional and conical diffusers.