Page 135 - Fluid Power Engineering

P. 135

Hydraulic Pumps 109

via a groove in the cam surface to the bore of the piston into the

pumping chamber.

Phase 3: The piston is at the lower dead point. The pumping

chamber is completely filled (maximum volume). The suction valve

and exit check valve are closed.

Phase 4: As the cam rotates, the piston is moved outwards in the

radial direction. The fluid is com pressed in the displacement chamber.

The increased fluid pressure opens the exit check valve, and the fluid

flows into the ring chan nel (13), which connects the pumping elements.

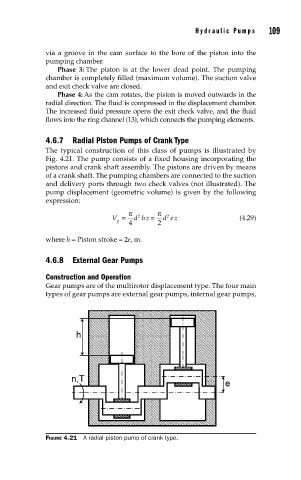

4.6.7 Radial Piston Pumps of Crank Type

The typical construction of this class of pumps is illustrated by

Fig. 4.21. The pump consists of a fixed housing incorporating the

pistons and crank shaft assembly. The pistons are driven by means

of a crank shaft. The pumping chambers are connected to the suction

and delivery ports through two check valves (not illustrated). The

pump displacement (geometric volume) is given by the following

expression:

π π

2

2

V = d hz = d ez (4.29)

g 4 2

where h = Piston stroke = 2e, m.

4.6.8 External Gear Pumps

Construction and Operation

Gear pumps are of the multirotor displacement type. The four main

types of gear pumps are external gear pumps, internal gear pumps,

FIGURE 4.21 A radial piston pump of crank type.