Page 130 - Fluid Catalytic Cracking Handbook

P. 130

FCC Catalysts 105

Star dard

FCCl Feed

Equilibrium n-Q Syringe Pump

Catalysts

! L J way Valve @

-"1^3

Coke Burn Off -

"I I

Reactor Furnace rJFlow Meter

Temp control Preheat L^«— <•) Purge N,

i— is

ri Zone

Tempcontrol Catalyst y Gas Product Sample

l~W

1 \

llllllln l „„ n .„ „ \

1

1

i

/ ^ ^^ [""F ', /'

7

/-''tL \ T

/ Cold Bath j salt Solution J-i / '

i Gas Collector

/ Gas Volume .

/ / Determination ,

/ r /

pent Catalyst Liquid Product Gas Product f

To Leco Analyzer for To Gas Chromatograph To Gas Chromatograth

Coke Determination for Analysis of for Component Analysis

\ Light Hydrocarbons and

Simulated Distillation

N

Material Balance

Detailed Produce Yields

Activity

Gas Factor, Coke Factor

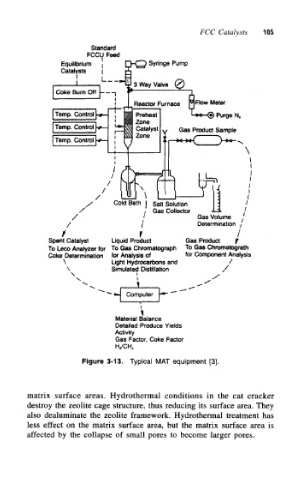

Figure 3-13. Typical MAT equipment [3].

matrix surface areas. Hydrothermal conditions in the cat cracker

destroy the zeolite cage structure, thus reducing its surface area. They

also dealuminate the zeolite framework. Hydrothermal treatment has

less effect on the matrix surface area, but the matrix surface area is

affected by the collapse of small pores to become larger pores.