Page 214 - Fluid mechanics, heat transfer, and mass transfer

P. 214

MIXING

192

Differences in these properties can also cause un- ➢ Segregating mixers have mainly diffusive me-

mixing or segregation during mixing or mechanical chanisms, encouraging the movement of indi-

jiggling of the mixture. vidual particles, making segregation more sig-

nificant. Non-impeller mixers tend to be of this

& Experience shows that materials with a size greater

type.

than 75 mm will segregate readily during mechanical

jiggling of the mixture, but those below 10 mm will ➢ Less segregating mixers have mainly convective

not segregate appreciably. mixing mechanisms. These are typically impeller

types in which blades, screws, ploughs, and so on

& Means of overcoming segregation and poor mixing

sweep groups of particles through the mixing

include the following:

zone.

➢ Comminution to smaller sizes.

. Illustrate the working of a solids static mixer for solids

➢ Use of powders with a narrow size distribution.

mixing.

➢ Use of the same volume-average diameter for all

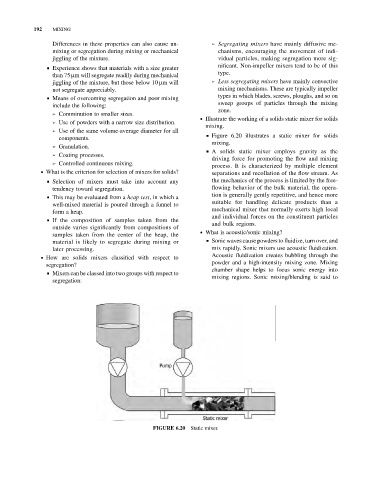

& Figure 6.20 illustrates a static mixer for solids

components.

mixing.

➢ Granulation.

& A solids static mixer employs gravity as the

➢ Coating processes.

driving force for promoting the flow and mixing

➢ Controlled continuous mixing.

process. It is characterized by multiple element

. What is the criterion for selection of mixers for solids? separations and recollation of the flow stream. As

& Selection of mixers must take into account any the mechanics of the process is limited by the free-

tendency toward segregation. flowing behavior of the bulk material, the opera-

tion is generally gently repetitive, and hence more

& This may be evaluated from a heap test, in which a

suitable for handling delicate products than a

well-mixed material is poured through a funnel to

mechanical mixer that normally exerts high local

form a heap.

and individual forces on the constituent particles

& If the composition of samples taken from the

and bulk regions.

outside varies significantly from compositions of

. What is acoustic/sonic mixing?

samples taken from the center of the heap, the

material is likely to segregate during mixing or & Sonic waves cause powders to fluidize, turn over, and

later processing. mix rapidly. Sonic mixers use acoustic fluidization.

Acoustic fluidization creates bubbling through the

. How are solids mixers classified with respect to

powder and a high-intensity mixing zone. Mixing

segregation?

chamber shape helps to focus sonic energy into

& Mixers can be classed into two groups with respect to

mixing regions. Sonic mixing/blending is said to

segregation:

FIGURE 6.20 Static mixer.