Page 228 - Fluid mechanics, heat transfer, and mass transfer

P. 228

206 TWO-PHASE FLOW SYSTEMS

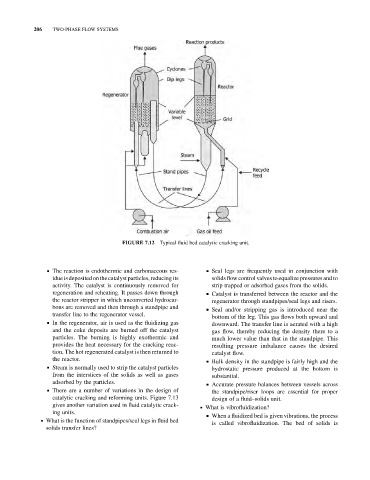

FIGURE 7.12 Typical fluid bed catalytic cracking unit.

& The reaction is endothermic and carbonaceous res- & Seal legs are frequently used in conjunction with

idue isdeposited onthe catalyst particles, reducing its solids flow control valves to equalize pressures and to

activity. The catalyst is continuously removed for strip trapped or adsorbed gases from the solids.

regeneration and reheating. It passes down through & Catalyst is transferred between the reactor and the

the reactor stripper in which unconverted hydrocar- regenerator through standpipes/seal legs and risers.

bons are removed and then through a standpipe and & Seal and/or stripping gas is introduced near the

transfer line to the regenerator vessel.

bottom of the leg. This gas flows both upward and

& In the regenerator, air is used as the fluidizing gas

downward. The transfer line is aerated with a high

and the coke deposits are burned off the catalyst gas flow, thereby reducing the density there to a

particles. The burning is highly exothermic and much lower value than that in the standpipe. This

provides the heat necessary for the cracking reac- resulting pressure imbalance causes the desired

tion. The hot regenerated catalyst is then returned to catalyst flow.

the reactor. & Bulk density in the standpipe is fairly high and the

& Steam is normally used to strip the catalyst particles

hydrostatic pressure produced at the bottom is

from the interstices of the solids as well as gases substantial.

adsorbed by the particles.

& Accurate pressure balances between vessels across

& There are a number of variations in the design of the standpipe/riser loops are essential for proper

catalytic cracking and reforming units. Figure 7.13 design of a fluid–solids unit.

gives another variation used in fluid catalytic crack- . What is vibrofluidization?

ing units.

& When a fluidized bed is given vibrations, the process

. What is the function of standpipes/seal legs in fluid bed

is called vibrofluidization. The bed of solids is

solids transfer lines?