Page 229 - Fluid mechanics, heat transfer, and mass transfer

P. 229

TWO-PHASE FLOW 207

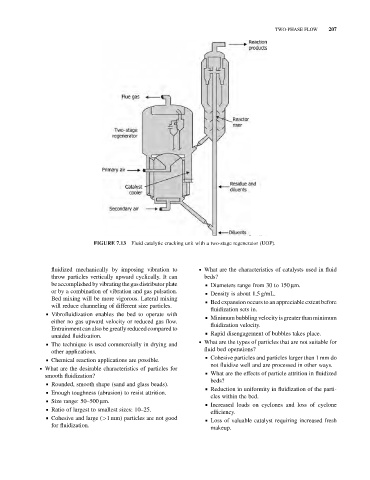

FIGURE 7.13 Fluid catalytic cracking unit with a two-stage regenerator (UOP).

fluidized mechanically by imposing vibration to . What are the characteristics of catalysts used in fluid

throw particles vertically upward cyclically. It can beds?

be accomplished by vibrating thegas distributor plate & Diameters range from 30 to 150 mm.

or by a combination of vibration and gas pulsation. & Density is about 1.5 g/mL.

Bed mixing will be more vigorous. Lateral mixing

& Bed expansion occurs to an appreciable extent before

will reduce channeling of different size particles.

fluidization sets in.

& Vibrofluidization enables the bed to operate with

& Minimum bubbling velocity is greater than minimum

either no gas upward velocity or reduced gas flow.

fluidization velocity.

Entrainment can also be greatly reduced compared to

& Rapid disengagement of bubbles takes place.

unaided fluidization.

. What are the types of particles that are not suitable for

& The technique is used commercially in drying and

fluid bed operations?

other applications.

& Cohesive particles and particles larger than 1 mm do

& Chemical reaction applications are possible.

not fluidize well and are processed in other ways.

. What are the desirable characteristics of particles for

& What are the effects of particle attrition in fluidized

smooth fluidization?

beds?

& Rounded, smooth shape (sand and glass beads).

& Reduction in uniformity in fluidization of the parti-

& Enough toughness (abrasion) to resist attrition.

cles within the bed.

& Size range: 50–500 mm.

& Increased loads on cyclones and loss of cyclone

& Ratio of largest to smallest sizes: 10–25.

efficiency.

& Cohesive and large (>1 mm) particles are not good

& Loss of valuable catalyst requiring increased fresh

for fluidization.

makeup.