Page 226 - Fluid mechanics, heat transfer, and mass transfer

P. 226

204 TWO-PHASE FLOW SYSTEMS

& For N Fr < 1, particulate fluidization normally occurs,

and for N Fr > 1, aggregative fluidization takes place.

& For fluidization involving liquid–solid systems,

much lower values of Froude numbers are involved

because much lower values of minimum velocities

are involved for fluidization. Uniformity for fluidi-

zation in the case of liquids is much more compared

to gas-phase fluidization.

. How does pressure drop vary with velocity in fluid–

solid beds? Illustrate.

& As the superficial velocity approaches the minimum

fluidization velocity, V mf , the bed starts to expand,

and when the particles are no longer in physical

contact with one another, the bed is fluidized. DP

then becomes lower because of the increased voi-

dage, and consequently, the weight of particles per

unit height of bed is smaller. This drop continues until

the velocity is high enough for transport of the

material to take place and DP then starts to increase

again because the frictional drag of the fluid at the

walls of the pipe starts to become significant.

& Figure 7.11 illustrates the history of transformation

of pressure drop from fixed bed to fluidized bed

to pneumatic conveyance as superficial velocity

increases.

. Give the equation for minimum fluidization velocity.

3 2

V mf ¼ 0:0055½« =ð1 « mf Þd ðr rÞg=m; ð7:12Þ

mf s

where « mf is the void fraction.

& This equation is based on the Kozeny–Karman equa-

tion for pressure drop for fixed beds and is applicable

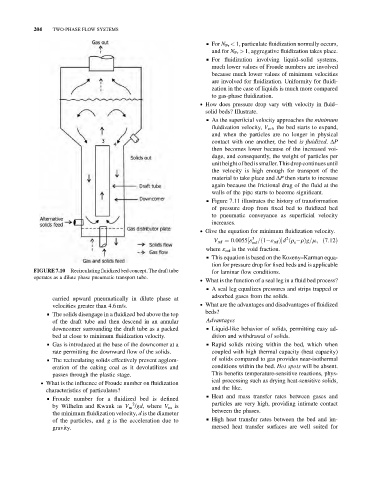

FIGURE 7.10 Recirculating fluidized bed concept. The draft tube for laminar flow conditions.

operates as a dilute phase pneumatic transport tube.

. What is the function of a seal leg in a fluid bed process?

& A seal leg equalizes pressures and strips trapped or

adsorbed gases from the solids.

carried upward pneumatically in dilute phase at

velocities greater than 4.6 m/s. . What are the advantages and disadvantages of fluidized

beds?

& The solids disengage in a fluidized bed above the top

of the draft tube and then descend in an annular Advantages

downcomer surrounding the draft tube as a packed & Liquid-like behavior of solids, permitting easy ad-

bed at close to minimum fluidization velocity. dition and withdrawal of solids.

& Gas is introduced at the base of the downcomer at a & Rapid solids mixing within the bed, which when

rate permitting the downward flow of the solids. coupled with high thermal capacity (heat capacity)

& The recirculating solids effectively prevent agglom- of solids compared to gas provides near-isothermal

eration of the caking coal as it devolatilizes and conditions within the bed. Hot spots will be absent.

passes through the plastic stage. This benefits temperature-sensitive reactions, phys-

ical processing such as drying heat-sensitive solids,

. What is the influence of Froude number on fluidization

and the like.

characteristics of particulates?

& Heat and mass transfer rates between gases and

& Froude number for a fluidized bed is defined

2

by Wilhelm and Kwauk as V m /gd,where V m is particles are very high, providing intimate contact

between the phases.

the minimum fluidization velocity, d is the diameter

of the particles, and g is the acceleration due to & High heat transfer rates between the bed and im-

gravity. mersed heat transfer surfaces are well suited for