Page 79 - Fluid mechanics, heat transfer, and mass transfer

P. 79

PIPING, SEALS, AND VALVES

56

FIGURE 3.16 Different types of valves for solids flow.

. Name and illustrate different types of valves used for

solids flow.

& Typical solids flow valves are shown in Figure 3.16.

. What are the different problems associated with valves?

& A high DP through a valve creates a number of

problems, such as cavitation, hammer effects, flash-

ing, choked flow, high noise levels and vibration,

leading to erosion or cavitation damage, malfunction,

or poor performance.

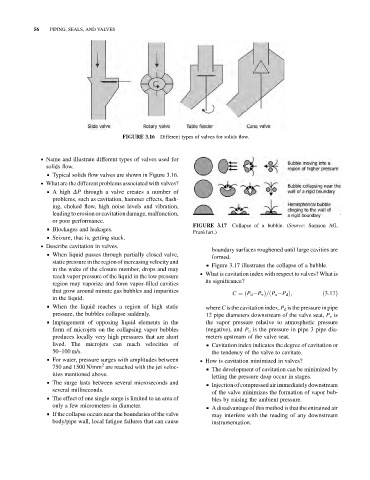

Collapse of a bubble. (Source: Samson AG,

& Blockages and leakages. FIGURE 3.17

Frankfurt.)

& Seizure, that is, getting stuck.

. Describe cavitation in valves.

boundary surfaces roughened until large cavities are

& When liquid passes through partially closed valve,

formed.

static pressure in the regionofincreasing velocityand

& Figure 3.17 illustrates the collapse of a bubble.

in the wake of the closure member, drops and may

. What is cavitation index with respect to valves? What is

reach vapor pressure of the liquid in the low pressure

its significance?

region may vaporize and form vapor-filled cavities

that grow around minute gas bubbles and impurities

C ¼ðP d P v Þ=ðP u P d Þ; ð3:17Þ

in the liquid.

& When the liquid reaches a region of high static

where C is the cavitation index,P d is the pressure in pipe

pressure, the bubbles collapse suddenly. 12 pipe diameters downstream of the valve seat, P v is

& Impingement of opposing liquid elements in the the vapor pressure relative to atmospheric pressure

form of microjets on the collapsing vapor bubbles (negative), and P u is the pressure in pipe 3 pipe dia-

produces locally very high pressures that are short meters upstream of the valve seat.

lived. The microjets can reach velocities of & Cavitation index indicates the degree of cavitation or

50–100 m/s. the tendency of the valve to cavitate.

& For water, pressure surges with amplitudes between . How is cavitation minimized in valves?

2

750 and 1500 N/mm are reached with the jet veloc- & The development of cavitation can be minimized by

ities mentioned above. letting the pressure drop occur in stages.

& The surge lasts between several microseconds and

& Injection of compressed air immediately downstream

several milliseconds.

of the valve minimizes the formation of vapor bub-

& The effect of one single surge is limited to an area of bles by raising the ambient pressure.

only a few micrometers in diameter. & A disadvantage of this method is that the entrained air

& If the collapse occurs near the boundaries of thevalve may interfere with the reading of any downstream

body/pipe wall, local fatigue failures that can cause instrumentation.