Page 75 - Fluid mechanics, heat transfer, and mass transfer

P. 75

PIPING, SEALS, AND VALVES

52

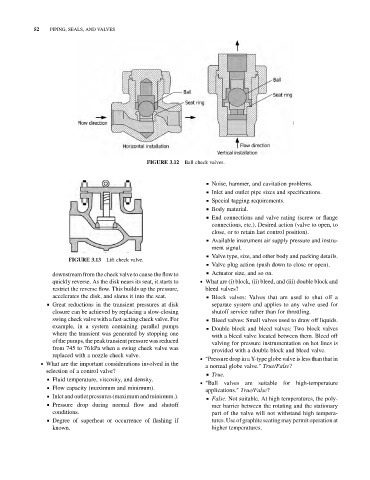

FIGURE 3.12 Ball check valves.

& Noise, hammer, and cavitation problems.

& Inlet and outlet pipe sizes and specifications.

& Special tagging requirements.

& Body material.

& End connections and valve rating (screw or flange

connections, etc.). Desired action (valve to open, to

close, or to retain last control position).

& Available instrument air supply pressure and instru-

ment signal.

& Valve type, size, and other body and packing details.

Lift check valve.

FIGURE 3.13

& Valve plug action (push down to close or open).

downstream from the check valve to cause the flow to & Actuator size, and so on.

quickly reverse. As the disk nears its seat, it starts to . What are (i) block, (ii) bleed, and (iii) double block and

restrict the reverse flow. This builds up the pressure, bleed valves?

accelerates the disk, and slams it into the seat. & Block valves: Valves that are used to shut off a

& Great reductions in the transient pressures at disk separate system and applies to any valve used for

closure can be achieved by replacing a slow-closing shutoff service rather than for throttling.

swing check valve with a fast-acting check valve. For & Bleed valves: Small valves used to draw off liquids.

example, in a system containing parallel pumps & Double block and bleed valves: Two block valves

where the transient was generated by stopping one with a bleed valve located between them. Bleed off

of the pumps, the peak transient pressurewas reduced valving for pressure instrumentation on hot lines is

from 745 to 76 kPa when a swing check valve was

provided with a double block and bleed valve.

replaced with a nozzle check valve.

. Pressure drop in a Y-type globe valve is less than that in

. What are the important considerations involved in the

a normal globe valve. True/False?

selection of a control valve?

& True.

& Fluid temperature, viscosity, and density.

. Ball valves are suitable for high-temperature

& Flow capacity (maximum and minimum).

applications. True/False?

& Inlet and outlet pressures (maximum and minimum.).

& False. Not suitable. At high temperatures, the poly-

& Pressure drop during normal flow and shutoff

mer barrier between the rotating and the stationary

conditions. part of the valve will not withstand high tempera-

& Degree of superheat or occurrence of flashing if tures. Use of graphite seating may permit operation at

known. higher temperatures.