Page 71 - Fluid mechanics, heat transfer, and mass transfer

P. 71

PIPING, SEALS, AND VALVES

48

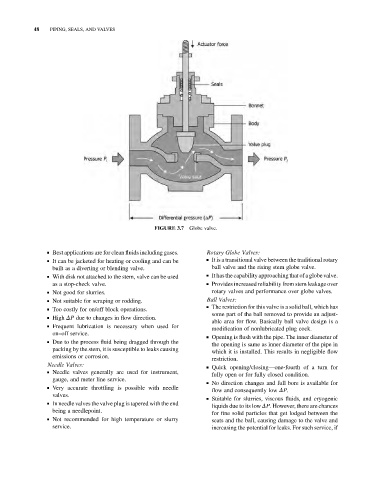

Globe valve.

FIGURE 3.7

& Best applications are for clean fluids including gases. Rotary Globe Valves:

& It can be jacketed for heating or cooling and can be & It is a transitional valve between the traditional rotary

built as a diverting or blending valve. ball valve and the rising stem globe valve.

& With disk not attached to the stem, valve can be used & It has the capability approaching that of aglobevalve.

as a stop-check valve. & Provides increased reliability from stem leakage over

& Not good for slurries. rotary valves and performance over globe valves.

& Not suitable for scraping or rodding. Ball Valves:

& The restriction for this valve is a solid ball, which has

& Too costly for on/off block operations.

some part of the ball removed to provide an adjust-

& High DP due to changes in flow direction.

able area for flow. Basically ball valve design is a

& Frequent lubrication is necessary when used for

modification of nonlubricated plug cock.

on–off service.

& Opening is flush with the pipe. The inner diameter of

& Due to the process fluid being dragged through the

the opening is same as inner diameter of the pipe in

packing by the stem, it is susceptible to leaks causing

which it is installed. This results in negligible flow

emissions or corrosion.

restriction.

Needle Valves: & Quick opening/closing—one-fourth of a turn for

& Needle valves generally are used for instrument,

fully open or for fully closed condition.

gauge, and meter line service.

& No direction changes and full bore is available for

& Very accurate throttling is possible with needle

flow and consequently low DP.

valves.

& Suitable for slurries, viscous fluids, and cryogenic

& In needle valves thevalve plug is tapered with the end

liquids due to its low DP. However, there are chances

being a needlepoint.

for fine solid particles that get lodged between the

& Not recommended for high temperature or slurry

seats and the ball, causing damage to the valve and

service. increasing the potential for leaks. For such service, if