Page 70 - Fluid mechanics, heat transfer, and mass transfer

P. 70

VALVES 47

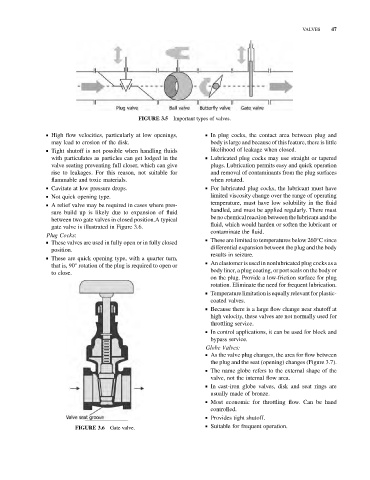

Important types of valves.

FIGURE 3.5

& High flow velocities, particularly at low openings, & In plug cocks, the contact area between plug and

may lead to erosion of the disk. body is large and because of this feature, there is little

& Tight shutoff is not possible when handling fluids likelihood of leakage when closed.

with particulates as particles can get lodged in the & Lubricated plug cocks may use straight or tapered

valve seating preventing full closer, which can give plugs. Lubrication permits easy and quick operation

rise to leakages. For this reason, not suitable for and removal of contaminants from the plug surfaces

flammable and toxic materials. when rotated.

& Cavitate at low pressure drops. & For lubricated plug cocks, the lubricant must have

& Not quick opening type. limited viscosity change over the range of operating

temperature, must have low solubility in the fluid

& A relief valve may be required in cases where pres-

handled, and must be applied regularly. There must

sure build up is likely due to expansion of fluid

be no chemical reaction betweenthe lubricant and the

between two gate valves in closed position.A typical

fluid, which would harden or soften the lubricant or

gate valve is illustrated in Figure 3.6.

contaminate the fluid.

Plug Cocks:

& These are limited to temperatures below 260 C since

& These valves are used in fully open or in fully closed

differential expansion between the plug and the body

position.

results in seizure.

& These are quick opening type, with a quarter turn,

& An elastomer is used in nonlubricated plug cocks as a

that is, 90 rotation of the plug is required to open or

body liner, a plug coating, or port seals on the body or

to close.

on the plug. Provide a low-friction surface for plug

rotation. Eliminate the need for frequent lubrication.

& Temperature limitation is equally relevant for plastic-

coated valves.

& Because there is a large flow change near shutoff at

high velocity, these valves are not normally used for

throttling service.

& In control applications, it can be used for block and

bypass service.

Globe Valves:

& As the valve plug changes, the area for flow between

the plug and the seat (opening) changes (Figure 3.7).

& The name globe refers to the external shape of the

valve, not the internal flow area.

& In cast-iron globe valves, disk and seat rings are

usually made of bronze.

& Most economic for throttling flow. Can be hand

controlled.

& Provides tight shutoff.

& Suitable for frequent operation.

Gate valve.

FIGURE 3.6