Page 73 - Fluid mechanics, heat transfer, and mass transfer

P. 73

PIPING, SEALS, AND VALVES

50

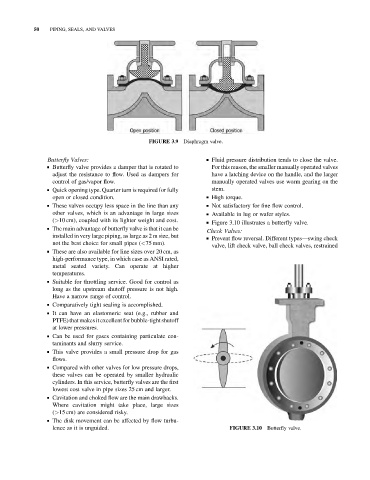

Diaphragm valve.

FIGURE 3.9

Butterfly Valves: & Fluid pressure distribution tends to close the valve.

& Butterfly valve provides a damper that is rotated to For this reason, the smaller manually operated valves

adjust the resistance to flow. Used as dampers for have a latching device on the handle, and the larger

control of gas/vapor flow. manually operated valves use worm gearing on the

& Quick opening type. Quarter turn is required for fully stem.

open or closed condition. & High torque.

& These valves occupy less space in the line than any & Not satisfactory for fine flow control.

other valves, which is an advantage in large sizes & Available in lug or wafer styles.

(>10 cm), coupled with its lighter weight and cost.

& Figure 3.10 illustrates a butterfly valve.

& The main advantage of butterfly valve is that it can be

Check Valves:

installed in very large piping, as large as 2 m size, but

& Prevent flow reversal. Different types—swing check

not the best choice for small pipes (<75 mm).

valve, lift check valve, ball check valves, restrained

& These are also available for line sizes over 20 cm, as

high-performance type, in which case as ANSI rated,

metal seated variety. Can operate at higher

temperatures.

& Suitable for throttling service. Good for control as

long as the upstream shutoff pressure is not high.

Have a narrow range of control.

& Comparatively tight sealing is accomplished.

& It can have an elastomeric seat (e.g., rubber and

PTFE) that makes it excellent for bubble-tight shutoff

at lower pressures.

& Can be used for gases containing particulate con-

taminants and slurry service.

& This valve provides a small pressure drop for gas

flows.

& Compared with other valves for low pressure drops,

these valves can be operated by smaller hydraulic

cylinders. In this service, butterfly valves are the first

lowest cost valve in pipe sizes 25 cm and larger.

& Cavitation and choked flow are the main drawbacks.

Where cavitation might take place, large sizes

(>15 cm) are considered risky.

& The disk movement can be affected by flow turbu-

lence as it is unguided. FIGURE 3.10 Butterfly valve.