Page 334 - Forensic Structural Engineering Handbook

P. 334

TEMPORARY STRUCTURES IN CONSTRUCTION 10.23

(c)

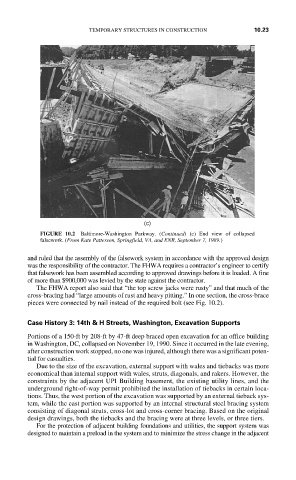

FIGURE 10.2 Baltimore-Washington Parkway. (Continued) (c) End view of collapsed

falsework. (From Kate Patterson, Springfield, VA, and ENR, September 7, 1989.)

and ruled that the assembly of the falsework system in accordance with the approved design

was the responsibility of the contractor. The FHWA requires a contractor’s engineer to certify

that falsework has been assembled according to approved drawings before it is loaded. A fine

of more than $900,000 was levied by the state against the contractor.

The FHWA report also said that “the top screw jacks were rusty” and that much of the

cross-bracing had “large amounts of rust and heavy pitting.” In one section, the cross-brace

pieces were connected by nail instead of the required bolt (see Fig. 10.2).

Case History 3: 14th & H Streets, Washington, Excavation Supports

Portions of a 150-ft by 208-ft by 47-ft deep braced open excavation for an office building

in Washington, DC, collapsed on November 19, 1990. Since it occurred in the late evening,

after construction work stopped, no one was injured, although there was a significant poten-

tial for casualties.

Due to the size of the excavation, external support with wales and tiebacks was more

economical than internal support with wales, struts, diagonals, and rakers. However, the

constraints by the adjacent UPI Building basement, the existing utility lines, and the

underground right-of-way permit prohibited the installation of tiebacks in certain loca-

tions. Thus, the west portion of the excavation was supported by an external tieback sys-

tem, while the east portion was supported by an internal structural steel bracing system

consisting of diagonal struts, cross-lot and cross-corner bracing. Based on the original

design drawings, both the tiebacks and the bracing were at three levels, or three tiers.

For the protection of adjacent building foundations and utilities, the support system was

designed to maintain a preload in the system and to minimize the stress change in the adjacent