Page 147 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 147

Compressor Best Practices Be st Practice 3.4

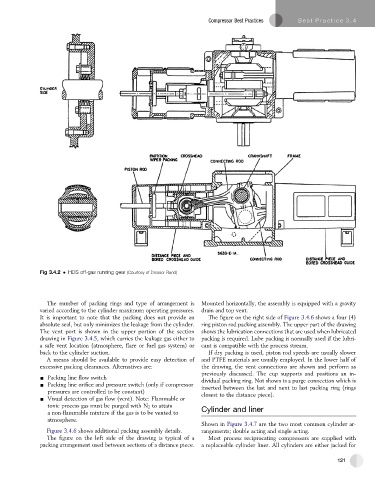

Fig 3.4.2 HDS off-gas running gear (Courtesy of Dresser Rand)

The number of packing rings and type of arrangement is Mounted horizontally, the assembly is equipped with a gravity

varied according to the cylinder maximum operating pressures. drain and top vent.

It is important to note that the packing does not provide an The figure on the right side of Figure 3.4.6 shows a four (4)

absolute seal, but only minimizes the leakage from the cylinder. ring piston rod packing assembly. The upper part of the drawing

The vent port is shown in the upper portion of the section shows the lubrication connections that are used when lubricated

drawing in Figure 3.4.5, which carries the leakage gas either to packing is required. Lube packing is normally used if the lubri-

a safe vent location (atmosphere, flare or fuel gas system) or cant is compatible with the process stream.

back to the cylinder suction. If dry packing is used, piston rod speeds are usually slower

A means should be available to provide easy detection of and PTFE materials are usually employed. In the lower half of

excessive packing clearances. Alternatives are: the drawing, the vent connections are shown and perform as

previously discussed. The cup supports and positions an in-

- Packing line flow switch

dividual packing ring. Not shown is a purge connection which is

- Packing line orifice and pressure switch (only if compressor inserted between the last and next to last packing ring (rings

pressures are controlled to be constant)

closest to the distance piece).

- Visual detection of gas flow (vent). Note: Flammable or

toxic process gas must be purged with N 2 to attain Cylinder and liner

a non-flammable mixture if the gas is to be vented to

atmosphere.

Shown in Figure 3.4.7 are the two most common cylinder ar-

Figure 3.4.6 shows additional packing assembly details. rangements; double acting and single acting.

The figure on the left side of the drawing is typical of a Most process reciprocating compressors are supplied with

packing arrangement used between sections of a distance piece. a replaceable cylinder liner. All cylinders are either jacked for

121