Page 152 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 152

Be st Practice 3 .4 Compressor Best Practices

the piston. Rod load limits the maximum compression ratio Cylinder and packing lubricators

that a cylinder can tolerate. This is the reason that many

first stage cylinders are supplied with a suction pressure Whenever mineral oil is compatible with the process, lubricators

switch. Rod reversal is necessary so that the piston rod re- will be used. Lubricators can be either a positive displacement or

action forces on the crosshead pin will change allowing oil to dynamic type. It is usual to review lubrication details in the

enter the pin bushing. If the position of the pin in the appropriate instruction book. Lubricators will increase piston

bushing did not change (reverse) with each stroke, the ring and packing life by reducing friction.

bushing could not be sufficiently lubricated and would pre- Figure 3.4.13 presents a typical lube oil system and its

maturely fail. function.

All instruments in the lube oil system should be continuously

Pulsation dampeners monitored (baseline and current conditions). Remember, com-

ponent (bearing) failure will occur if any major component in

the system fails to function.

Since the action of the piston is non-continuous, pressure pul-

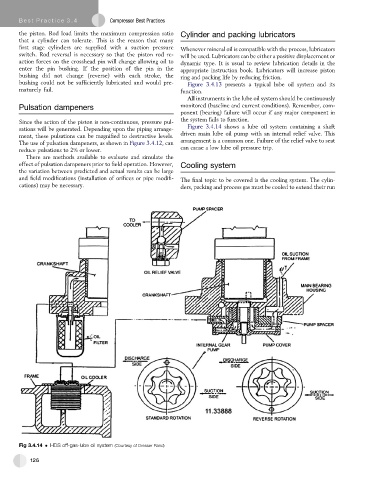

sations will be generated. Depending upon the piping arrange- Figure 3.4.14 shows a lube oil system containing a shaft

ment, these pulsations can be magnified to destructive levels. driven main lube oil pump with an internal relief valve. This

The use of pulsation dampeners, as shown in Figure 3.4.12, can arrangement is a common one. Failure of the relief valve to seat

reduce pulsations to 2% or lower. can cause a low lube oil pressure trip.

There are methods available to evaluate and simulate the

effect of pulsation dampeners prior to field operation. However, Cooling system

the variation between predicted and actual results can be large

and field modifications (installation of orifices or pipe modifi- The final topic to be covered is the cooling system. The cylin-

cations) may be necessary. ders, packing and process gas must be cooled to extend their run

Fig 3.4.14 HDS off-gas-lube oil system (Courtesy of Dresser Rand)

126