Page 156 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 156

Be st Practice 3 .7 Compressor Best Practices

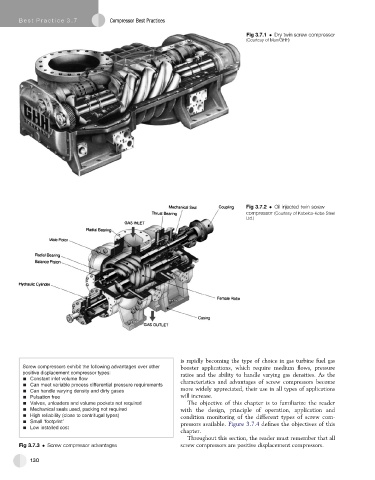

Fig 3.7.1 Dry twin screw compressor

(Courtesy of Man/GHH)

Fig 3.7.2 Oil injected twin screw

compressor (Courtesy of Kobelco-Kobe Steel

Ltd.)

is rapidly becoming the type of choice in gas turbine fuel gas

Screw compressors exhibit the following advantages over other booster applications, which require medium flows, pressure

positive displacement compressor types: ratios and the ability to handle varying gas densities. As the

Constant inlet volume flow characteristics and advantages of screw compressors become

Can meet variable process differential pressure requirements

Can handle varying density and dirty gases more widely appreciated, their use in all types of applications

Pulsation free will increase.

Valves, unloaders and volume pockets not required The objective of this chapter is to familiarize the reader

Mechanical seals used, packing not required with the design, principle of operation, application and

High reliability (close to centrifugal types) condition monitoring of the different types of screw com-

Small ‘footprint’

pressors available. Figure 3.7.4 defines the objectives of this

Low installed cost

chapter.

Throughout this section, the reader must remember that all

Fig 3.7.3 Screw compressor advantages screw compressors are positive displacement compressors.

130