Page 161 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 161

Compressor Best Practices Be st Practice 3.7

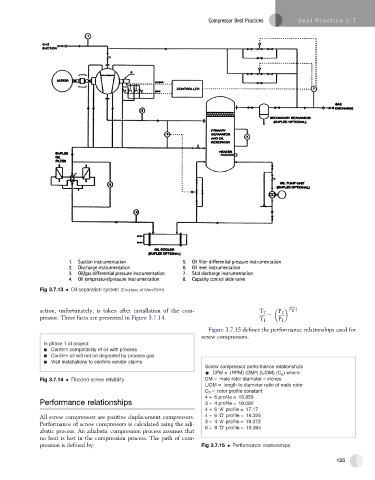

Fig 3.7.13 Oil separation system (Courtesy of Man/GHH)

K-1

action, unfortunately, is taken after installation of the com- T 2 P 2 ð K Þ

pressor. These facts are presented in Figure 3.7.14. T 1 ¼ P 1

Figure 3.7.15 defines the performance relationships used for

screw compressors.

In phase 1 of project:

Confirm compatibility of oil with process

Confirm oil will not be degraded by process gas

Visit installations to confirm vendor claims

Screw compressor performance relationships

3

CFM = (RPM) (DM ) (L/DM) (C 0 ) where:

Fig 3.7.14 Flooded screw reliability DM = male rotor diameter – inches

L/DM = length to diameter ratio of male rotor

C 0 = rotor profile constant

4 + 6 profile = 15.853

Performance relationships 3 + 4 profile = 18.082

4 + 6 ‘A’ profile = 17.17

All screw compressors are positive displacement compressors. 4 + 6 ‘D’ profile = 16.325

Performance of screw compressors is calculated using the adi- 3 + 4 ‘A’ profile = 19.372

abatic process. An adiabatic compression process assumes that 6 + 8 ‘D’ profile = 10.364

no heat is lost in the compression process. The path of com-

pression is defined by: Fig 3.7.15 Performance relationships

135