Page 157 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 157

Compressor Best Practices Be st Practice 3.7

As will be discussed in this section, all types of positive dis-

placement compressors present the designer with a challenge.

Define design features and component function

Present selection and application guidelines This challenge is to provide varying flow requirements to the

Inform regarding field condition monitoring requirements process system in a safe and reliable manner. You will discover

that the screw compressor industry has met the challenge in

a safe, reliable and most efficient way.

Fig 3.7.4 Screw compressor chapter objectives

Principles of operation

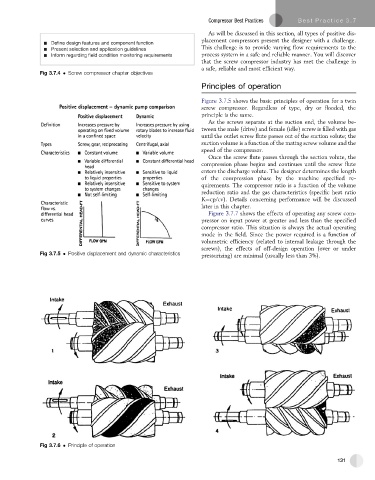

Figure 3.7.5 shows the basic principles of operation for a twin

screw compressor. Regardless of type, dry or flooded, the

principle is the same.

As the screws separate at the suction end, the volume be-

tween the male (drive) and female (idle) screw is filled with gas

until the outlet screw flute passes out of the suction volute; the

suction volume is a function of the mating screw volume and the

speed of the compressor.

Once the screw flute passes through the section volute, the

compression phase begins and continues until the screw flute

enters the discharge volute. The designer determines the length

of the compression phase by the machine specified re-

quirements. The compressor ratio is a function of the volume

reduction ratio and the gas characteristics (specific heat ratio

K¼cp/cv). Details concerning performance will be discussed

later in this chapter.

Figure 3.7.7 shows the effects of operating any screw com-

pressor on input power at greater and less than the specified

compressor ratio. This situation is always the actual operating

mode in the field. Since the power required is a function of

volumetric efficiency (related to internal leakage through the

screws), the effects of off-design operation (over or under

Fig 3.7.5 Positive displacement and dynamic characteristics pressurizing) are minimal (usually less than 3%).

Fig 3.7.6 Principle of operation

131