Page 160 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 160

Be st Practice 3 .7 Compressor Best Practices

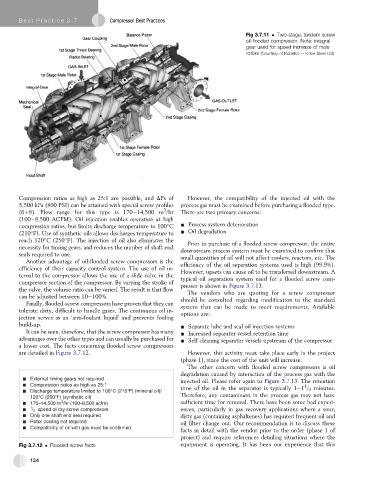

Fig 3.7.11 Two-stage, tandem screw

oil-flooded compressor. Note: integral

gear used for speed increase of male

rotors (Courtesy of Kobelco e Kobe Steel Ltd)

Compression ratios as high as 25:1 are possible, and DPs of However, the compatibility of the injected oil with the

5,500 kPa (800 PSI) can be attained with special screw profiles process gas must be examined before purchasing a flooded type.

3

(6þ8). Flow range for this type is 170e14,500 m /hr There are two primary concerns:

(100e8,500 ACFM). Oil injection enables operation at high

compression ratios, but limits discharge temperature to 100 C - Process system deterioration

(210 F). Use of synthetic oils allows discharges temperature to - Oil degradation

reach 120 C (250 F). The injection of oil also eliminates the Prior to purchase of a flooded screw compressor, the entire

necessity for timing gears, and reduces the number of shaft end downstream process system must be examined to confirm that

seals required to one. small quantities of oil will not affect coolers, reactors, etc. The

Another advantage of oil-flooded screw compressors is the efficiency of the oil separation systems used is high (99.9%).

efficiency of their capacity control system. The use of oil in- However, upsets can cause oil to be transferred downstream. A

ternal to the compressor allows the use of a slide valve in the typical oil separation system used for a flooded screw com-

compressor section of the compressor. By varying the stroke of

pressor is shown in Figure 3.7.13.

the valve, the volume ratio can be varied. The result is that flow The vendors who are quoting for a screw compressor

can be adjusted between 10e100%.

should be consulted regarding modification to the standard

Finally, flooded-screw compressors have proven that they can system that can be made to meet requirements. Available

tolerate dirty, difficult to handle gases. The continuous oil in- options are:

jection serves as an ‘anti-foulant liquid’ and prevents fouling

build-up. - Separate lube and seal oil injection systems

It can be seen, therefore, that the screw compressor has many - Increased separator vessel retention time

advantages over the other types and can usually be purchased for - Self cleaning separator vessels upstream of the compressor

a lower cost. The facts concerning flooded screw compressors

are detailed in Figure 3.7.12. However, this activity must take place early in the project

(phase 1), since the cost of the unit will increase.

The other concern with flooded screw compressors is oil

degradation caused by interaction of the process gas with the

External timing gears not required injected oil. Please refer again to Figure 3.7.13. The retention

Compression ratios as high as 25:1 time of the oil in the separator is typically 1e1 / 2 minutes.

1

Discharge temperature limited to 100°C (210°F) (mineral oil)/

120°C (250°F) (synthetic oil) Therefore, any contaminant in the process gas may not have

3

170–14,500 m /hr (100–8,500 acfm) sufficient time for removal. There have been some bad experi-

1

/ 3 speed of dry screw compressors ences, particularly in gas recovery applications where a sour,

Only one shaft end seal required dirty gas (containing asphaltenes) has required frequent oil and

Rotor cooling not required oil filter change out. Our recommendation is to discuss these

Compatibility of oil with gas must be confirmed

facts in detail with the vendor prior to the order (phase 1 of

project) and require references detailing situations where the

Fig 3.7.12 Flooded screw facts equipment is operating. It has been our experience that this

134