Page 153 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 153

Compressor Best Practices Be st Practice 3.5

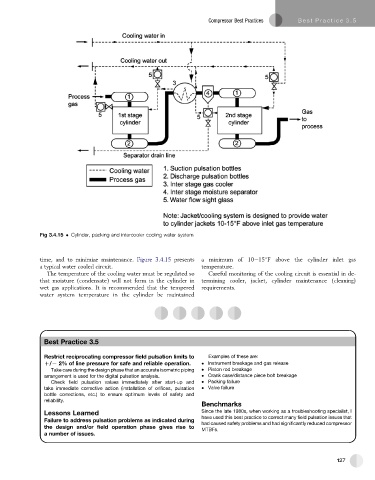

Fig 3.4.15 Cylinder, packing and intercooler cooling water system

time, and to minimize maintenance. Figure 3.4.15 presents a minimum of 10e15 F above the cylinder inlet gas

a typical water cooled circuit. temperature.

The temperature of the cooling water must be regulated so Careful monitoring of the cooling circuit is essential in de-

that moisture (condensate) will not form in the cylinder in termining cooler, jacket, cylinder maintenance (cleaning)

wet gas applications. It is recommended that the tempered requirements.

water system temperature in the cylinder be maintained

Best Practice 3.5

Restrict reciprocating compressor field pulsation limits to Examples of these are:

D/L 2% of line pressure for safe and reliable operation. Instrument breakage and gas release

Take care during the design phase that an accurate isometric piping Piston rod breakage

arrangement is used for the digital pulsation analysis. Crank case/distance piece bolt breakage

Check field pulsation values immediately after start-up and Packing failure

take immediate corrective action (installation of orifices, pulsation Valve failure

bottle corrections, etc.) to ensure optimum levels of safety and

reliability.

Benchmarks

Lessons Learned Since the late 1980s, when working as a troubleshooting specialist, I

have used this best practice to correct many field pulsation issues that

Failure to address pulsation problems as indicated during

had caused safety problems and had significantly reduced compressor

the design and/or field operation phase gives rise to MTBFs.

a number of issues.

127