Page 151 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 151

Compressor Best Practices Be st Practice 3.4

Fig 3.4.11 HDS off-gas-piston rod and piston (Courtesy of

Dresser Rand)

compounds are used. If non-lubricated service is required, PTFE

materials or other Teflon derivatives are used. Note also the

piston hollowed area for piston weight control. Rider band and

ring life is a function of piston speed, cylinder gas temperature

and cleanliness of the process gas. In many process applications,

a strainer is required upstream of the compressor to prevent

excessive ring wear.

Condition monitoring of rider band and piston ring wear can

be accomplished by measuring and trending the vertical dis-

tance between each piston rod and a fixed point (known as rod

drop). This can be accomplished either by mechanical or

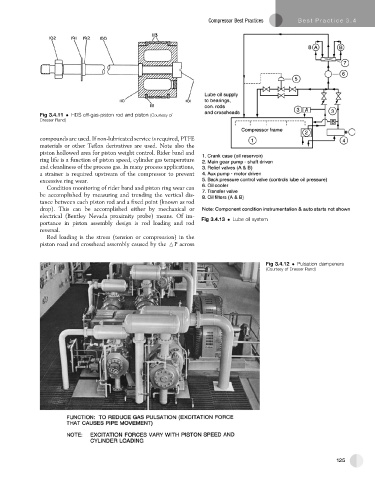

electrical (Bentley Nevada proximity probe) means. Of im- Fig 3.4.13 Lube oil system

portance in piston assembly design is rod loading and rod

reversal.

Rod loading is the stress (tension or compression) in the

piston road and crosshead assembly caused by the 6Pacross

Fig 3.4.12 Pulsation dampeners

(Courtesy of Dresser Rand)

125