Page 142 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 142

Be st Practice 3 .3 Compressor Best Practices

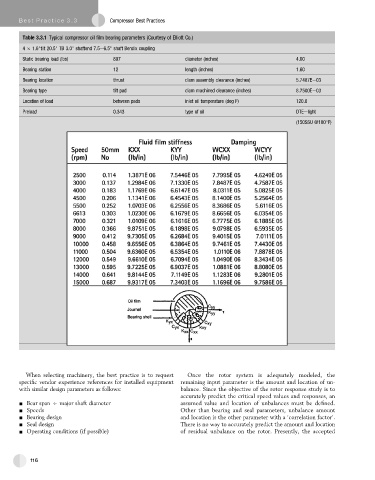

Table 3.3.1 Typical compressor oil film bearing parameters (Courtesy of Elliott Co.)

4 1.6"tilt 20.5" TB 3.0" shaftend 7.5e6.5" shaft Bendix coupling

Static bearing load (lbs) 897 diameter (inches) 4.00

Bearing station 12 length (inches) 1.60

Bearing location thrust diam assembly clearance (inches) 5.7487Ee03

Bearing type tilt pad diam machined clearance (inches) 8.7500Ee03

Location of load between pads inlet oil temperature (deg F) 120.0

Preload 0.343 type of oil DTEelight

(150SSU @100 F)

When selecting machinery, the best practice is to request Once the rotor system is adequately modeled, the

specific vendor experience references for installed equipment remaining input parameter is the amount and location of un-

with similar design parameters as follows: balance. Sincethe objectiveofthe rotorresponse study is to

accurately predict the critical speed values and responses, an

- Bear span O major shaft diameter assumed value and location of unbalances must be defined.

- Speeds Other than bearing and seal parameters, unbalance amount

- Bearing design and location is the other parameter with a ‘correlation factor’.

- Seal design There is no way to accurately predict the amount and location

- Operating conditions (if possible) of residual unbalance on the rotor. Presently, the accepted

116