Page 169 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 169

Compressor Best Practices Be st Practice 3.8

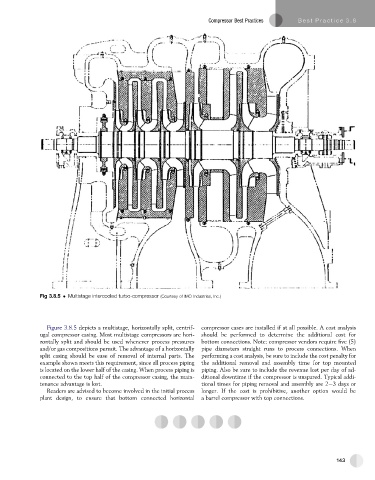

Fig 3.8.5 Multistage intercooled turbo-compressor (Courtesy of IMO Industries, Inc.)

Figure 3.8.5 depicts a multistage, horizontally split, centrif- compressor cases are installed if at all possible. A cost analysis

ugal compressor casing. Most multistage compressors are hori- should be performed to determine the additional cost for

zontally split and should be used whenever process pressures bottom connections. Note: compressor vendors require five (5)

and/or gas compositions permit. The advantage of a horizontally pipe diameters straight runs to process connections. When

split casing should be ease of removal of internal parts. The performing a cost analysis, be sure to include the cost penalty for

example shown meets this requirement, since all process piping the additional removal and assembly time for top mounted

is located on the lower half of the casing. When process piping is piping. Also be sure to include the revenue lost per day of ad-

connected to the top half of the compressor casing, the main- ditional downtime if the compressor is unspared. Typical addi-

tenance advantage is lost. tional times for piping removal and assembly are 2e3 days or

Readers are advised to become involved in the initial process longer. If the cost is prohibitive, another option would be

plant design, to ensure that bottom connected horizontal a barrel compressor with top connections.

143