Page 173 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 173

Compressor Best Practices Best Practice 3 .11

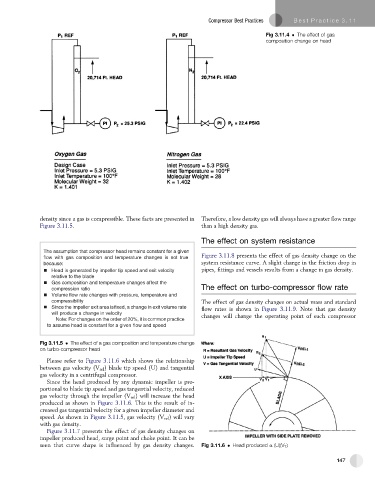

Fig 3.11.4 The effect of gas

composition change on head

density since a gas is compressible. These facts are presented in Therefore, a low density gas will always have a greater flow range

Figure 3.11.5. than a high density gas.

The effect on system resistance

The assumption that compressor head remains constant for a given

flow with gas composition and temperature changes is not true Figure 3.11.8 presents the effect of gas density change on the

because: system resistance curve. A slight change in the friction drop in

Head is generated by impeller tip speed and exit velocity pipes, fittings and vessels results from a change in gas density.

relative to the blade

Gas composition and temperature changes affect the

compression ratio The effect on turbo-compressor flow rate

Volume flow rate changes with pressure, temperature and

compressibility The effect of gas density changes on actual mass and standard

Since the impeller exit area isfixed, a change in exit volume rate flow rates is shown in Figure 3.11.9. Note that gas density

will produce a change in velocity changes will change the operating point of each compressor

Note: For changes on the order of 20%, it is common practice

to assume head is constant for a given flow and speed

Fig 3.11.5 The effect of a gas composition and temperature change

on turbo-compressor head

Please refer to Figure 3.11.6 which shows the relationship

between gas velocity (V rel ) blade tip speed (U) and tangential

gas velocity in a centrifugal compressor.

Since the head produced by any dynamic impeller is pro-

portional to blade tip speed and gas tangential velocity, reduced

gas velocity through the impeller (V rel ) will increase the head

produced as shown in Figure 3.11.6. This is the result of in-

creased gas tangential velocity for a given impeller diameter and

speed. As shown in Figure 3.11.5, gas velocity (V rel ) will vary

with gas density.

Figure 3.11.7 presents the effect of gas density changes on

impeller produced head, surge point and choke point. It can be

seen that curve shape is influenced by gas density changes. Fig 3.11.6 Head produced a (U)(V T )

147