Page 167 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 167

Compressor Best Practices Be st Practice 3.8

- Multistage radial split

- Multistage horizontal split

- Multistage integral gear

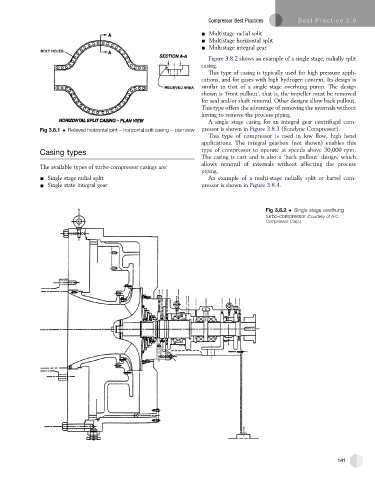

Figure 3.8.2 shows an example of a single stage, radially split

casing.

This type of casing is typically used for high pressure appli-

cations, and for gases with high hydrogen content. Its design is

similar to that of a single stage overhung pump. The design

shown is ‘front pullout’, that is, the impeller must be removed

for seal and/or shaft removal. Other designs allow back pullout.

This type offers the advantage of removing the internals without

having to remove the process piping.

A single stage casing for an integral gear centrifugal com-

Fig 3.8.1 Relieved horizontal joint e horizontal split casing e plan view pressor is shown in Figure 3.8.3 (Sundyne Compressor).

This type of compressor is used in low flow, high head

applications. The integral gearbox (not shown) enables this

Casing types type of compressor to operate at speeds above 30,000 rpm.

The casing is cast and is also a ‘back pullout’ design, which

allows removal of internals without affecting the process

The available types of turbo-compressor casings are:

piping.

- Single stage radial split An example of a multi-stage radially split or barrel com-

- Single state integral gear pressor is shown in Figure 3.8.4.

Fig 3.8.2 Single stage overhung

turbo-compressor (Courtesy of A-C

Compressor Corp.)

141