Page 393 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 393

Be st Practice 7 .7 Lube, Seal and Control Oil System Best Practices

prevent oil from entering the compressor case. The sizing of compressor, but too high a velocity could cause oil to enter

the orifice in the vent line of each drainer is critical, since it the compressor via the vent or reference line. Typical

ensures that all contaminated oil flow will enter the drainer. velocities in this line should be 4.6e6m/sec (15e20 ft/

Too low a velocity will allow contaminated oil to enter the sec).

Best Practice 7.7Practice 7.7

Best

Use centrifugal single stage pumps instead of screw Lessons Learned

pumps whenever possible, to increase the reliability of lube The most common cause of oil system induced unit trips is

oil systems. the failure of the backpressure control valve to respond to

The use of centrifugal pumps eliminates the need for relief and transient system changes (trip or slow speed reduction of

backpressure (bypass) control valves. the main turbine driven oil pump). The use of centrifugal

Malfunction of relief valves and/or backpressure control can cause

pumps eliminates the need for a backpressure control

an unscheduled shutdown of unit and hence result in significant rev-

valve.

enue loss.

Single stage centrifugal pumps can be used whenever the ambient

temperature along with the use of thermostatically controlled reservoir Benchmarks

heaters maintain an oil viscosity that allows the use of a centrifugal This best practice has been used since the mid-1980s to optimize the

pump (oil viscosity is low enough to minimize the effect of viscosity on reliability of oil systems, and to achieve compressor train reliabilities

centrifugal pump power e low viscosity correction factors). exceeding 99.7%

B.P. 7.7. Supporting Material

The pumps

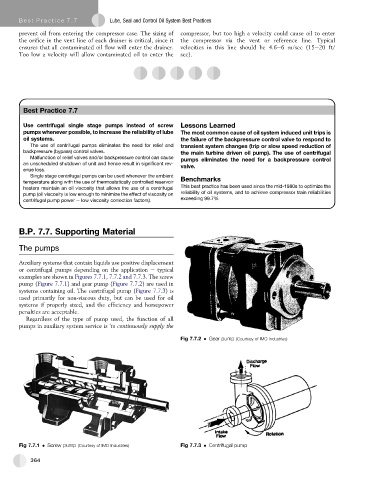

Auxiliary systems that contain liquids use positive displacement

or centrifugal pumps depending on the application e typical

examples are shown in Figures 7.7.1, 7.7.2 and 7.7.3. The screw

pump (Figure 7.7.1) and gear pump (Figure 7.7.2) are used in

systems containing oil. The centrifugal pump (Figure 7.7.3)is

used primarily for non-viscous duty, but can be used for oil

systems if properly sized, and the efficiency and horsepower

penalties are acceptable.

Regardless of the type of pump used, the function of all

pumps in auxiliary system service is ‘to continuously supply the

Fig 7.7.2 Gear pump (Courtesy of IMO Industries)

Fig 7.7.1 Screw pump (Courtesy of IMO Industries) Fig 7.7.3 Centrifugal pump

364