Page 390 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 390

Lube, Seal and Control Oil System Best Practices Be st Practice 7.5

10. Minimum reservoir free surface area: 1.3 Model ______________

2

2

¼ 232 cm /LPM of normal flow (0.25 ft. /GPM) 1.4 Action e direct or reverse ______________

1.5 Valve plug type ______________

¼ 0.25 (1)

2 1.6 Failure mode ______________

¼ ft.

1.7 Actuator size ______________

1.8 Actuator force available/force ______________

Confirm reservoir internals, material, etc. meet data sheet required

and specifications required. Review reservoir internal

1.9 Maximum valve C v ¼ ______________

drawing.

1.10 Operating C v min. (one pump dirty system) ¼ ______________

F. Reservoir heating requirements 1.11 Operating C v max. ¼ ______________

(two pumps clean system)

Type Electric Steam

Note: Operating C v s should be between 10% e 90% of valve max. C v .

Time to head oil from C( F) to _________ C( F) ¼

_________ _________ Sensing line pulsation snubber required? If so, confirm proper

Hours orientation. Confirm fast response is to open or close valve.

1. Calculated heat load ¼ _________kJ (BTU)

(minus reservoir H2. Transfer valve(s)

heat loss)

2. Heater size kJ/HR ðF1Þ 2.1 Make ______________

¼

(BTU/HR) Total time allowed ðhoursÞ 2.2 Model ______________

3. Electric heater max ¼ _____________ 2.3 Size ______________

watt density 2.4 Plus type e Taper, Straight, Globe ______________

2.5 Lifting jack required? ______________

Note: Confirm if heaters can be removed without draining reservoir. 2.6 Tight shut-off required? ______________

2.7 Max DP on changeover ______________

G. Supply pipe velocity

Maximum velocity 1.2e1.8 m/sec (4e6 ft/sec) H3. Temperature control valve(s)

Maximum console supply pipe velocity ¼ __________m/sec (ft/sec)

Maximum unit supply pipe velocity ¼ __________ m/sec (ft/sec) 3.1 Make ______________

3.2 Model ______________

3.3 Size ______________

H. Control valve sizing

3.4 Normal flow liters/min (GPM) ______________

H1. Bypass (back pressure) valve 3.5 Temperature range C( F) ______________

3.6 Valve max operating C v ______________

1.1 Type: self acting, pneumatic or electric ______________ (If 2-way valve, C v must be based on clean cooler)

controller

1.2 Make ______________ Note: Butterfly type valve often used for 2-way applications.

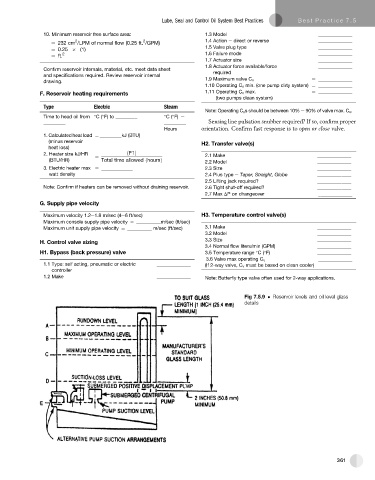

Fig 7.5.9 Reservoir levels and oil level glass

details

361