Page 391 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 391

Be st Practice 7 .5 Lube, Seal and Control Oil System Best Practices

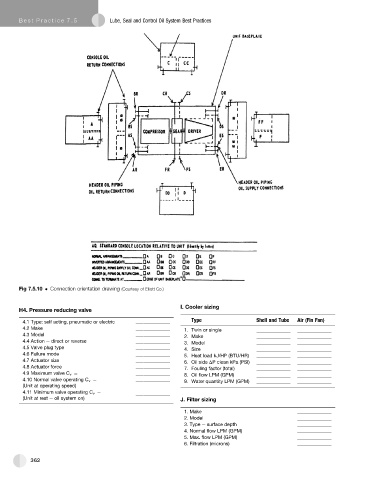

Fig 7.5.10 Connection orientation drawing (Courtesy of Elliott Co.)

I. Cooler sizing

H4. Pressure reducing valve

Type Shell and Tube Air (Fin Fan)

4.1 Type: self acting, pneumatic or electric ______________

4.2 Make ______________ 1. Twin or single ______________ ______________

4.3 Model ______________ 2. Make ______________ ______________

4.4 Action e direct or reverse ______________

3. Model ______________ ______________

4.5 Valve plug type ______________ 4. Size ______________ ______________

4.6 Failure mode ______________

5. Heat load kJ/HP (BTU/HR) ______________ ______________

4.7 Actuator size ______________ 6. Oil side DP clean kPa (PSI) ______________ ______________

4.8 Actuator force ______________ 7. Fouling factor (total) ______________ ______________

4.9 Maximum valve C v ¼ ______________ 8. Oil flow LPM (GPM) ______________ ______________

4.10 Normal valve operating C v ¼ ______________ 9. Water quantity LPM (GPM) ______________ ______________

(Unit at operating speed)

4.11 Minimum valve operating C v ¼ ______________

(Unit at rest e oil system on) J. Filter sizing

1. Make ______________

2. Model ______________

3. Type e surface depth ______________

4. Normal flow LPM (GPM) ______________

5. Max. flow LPM (GPM) ______________

6. Filtration (microns) ______________

362