Page 389 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 389

Be st Practice 7 .5 Lube, Seal and Control Oil System Best Practices

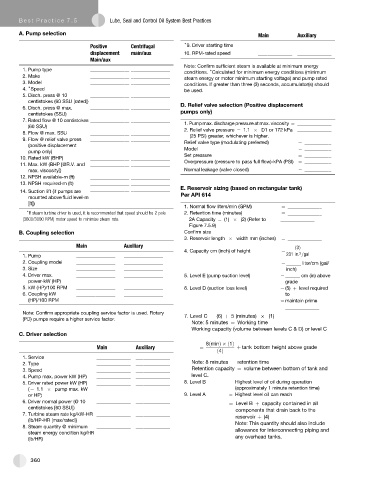

A. Pump selection Main Auxiliary

Positive Centrifugal ) 9. Driver starting time

displacement main/aux 10. RPM-rated speed ______________ ______________

Main/aux

Note: Confirm sufficient steam is available at minimum energy

1. Pump type ________________ ________________ )

conditions. Calculated for minimum energy conditions (minimum

2. Make ________________ ________________

steam energy or motor minimum starting voltage) and pump rated

3. Model ________________ ________________ conditions. If greater than three (3) seconds, accumulator(s) should

)

4. Speed ________________ ________________ be used.

5. Disch. press @ 10 ________________ ________________

centistokes (60 SSU [rated])

D. Relief valve selection (Positive displacement

6. Disch. press @ max. ________________ ________________

pumps only)

centistokes (SSU)

7. Rated flow @ 10 centistokes ________________ ________________ 1. Pump max. discharge pressure at max. viscosity ¼ ______________

(60 SSU)

2. Relief valve pressure ¼ 1.1 D1 or 172 kPa ______________

8. Flow @ max. SSU ________________ ________________

(25 PSI) greater, whichever is higher.

9. Flow @ relief valve press ________________ ________________ Relief valve type (modulating preferred) ¼ ___________

(positive displacement

Model ¼ ___________

pump only)

10. Rated kW (BHP) ________________ ________________ Set pressure ¼ ___________

Overpressure (pressure to pass full flow)-kPA (PSI) ¼ ___________

11. Max. kW (BHP [@R.V. and ________________ ________________

max. viscosity]) Normal leakage (valve closed) ¼ ___________

12. NPSH available-m (ft) ________________ ________________

13. NPSH required-m (ft) ________________ ________________

14. Suction lift (if pumps are ________________ ________________ E. Reservoir sizing (based on rectangular tank)

Per API 614

mounted above fluid level-m

[ft])

1. Normal flow liters/min (GPM) ¼ ______________

)

If steam turbine driver is used, it is recommended that speed should be 2 pole 2. Retention time (minutes) ¼ ______________

(3600/3000 RPM) motor speed to minimize steam rate. 2A Capacity ¼ (1) (2) (Refer to ______________

Figure 7.5.9)

B. Coupling selection Confirm size

3. Reservoir length width mm (inches) ¼ ______________

Main Auxiliary

4. Capacity cm (inch) of height ¼ ð3Þ

3

1. Pump ________________ ________________ 231 in: =gal

2. Coupling model ________________ ________________ ¼ ______ liter/cm (gal/

3. Size ________________ ________________ inch)

4. Driver max. ________________ ________________ 5. Level E (pump suction level) ¼ ______ cm (in) above

power-kW (HP) grade

5. kW (HP)/100 RPM ________________ ________________ 6. Level D (suction loss level) ¼ (5) þ level required

6. Coupling kW ________________ ________________ to

(HP)/100 RPM ¼ maintain prime

¼ ______________

Note: Confirm appropriate coupling service factor is used. Rotary 7. Level C ¼ (6) þ 5 (minutes) (1)

(PD) pumps require a higher service factor.

Note: 5 minutes ¼ Working time

Working capacity (volume between levels C & D) or level C

C. Driver selection

Main Auxiliary ¼ 8ðminÞ ð1Þ þ tank bottom height above grade

ð4Þ

1. Service ______________ ______________

2. Type ______________ ______________ Note: 8 minutes ¼ retention time

3. Speed ______________ ______________ Retention capacity ¼ volume between bottom of tank and

4. Pump max. power kW (HP) ______________ ______________ level C.

5. Driver rated power kW (HP) ______________ ______________ 8. Level B ¼ Highest level of oil during operation

( ¼ 1.1 pump max. kW (approximately 1 minute retention time)

or HP) 9. Level A ¼ Highest level oil can reach

6. Driver normal power (@ 10 ______________ ______________ ¼ Level B þ capacity contained in all

centistokes [60 SSU])

components that drain back to the

7. Turbine steam rate kg/kW-HR ______________ ______________

reservoir O (4)

(lb/HP-HR [max/rated])

Note: This quantity should also include

8. Steam quantity @ minimum ______________ ______________

steam energy condition kg/HR allowance for interconnecting piping and

(lb/HR) any overhead tanks.

360