Page 434 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 434

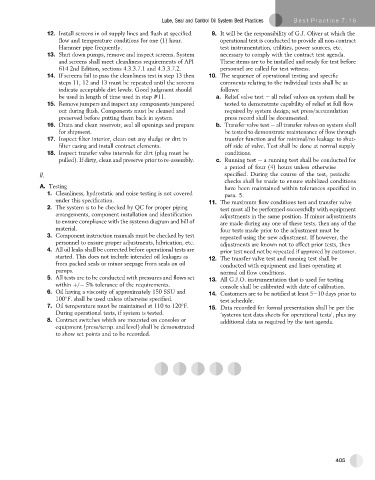

Lube, Seal and Control Oil System Best Practices Best Practice 7 .16

12. Install screens in oil supply lines and flush at specified 9. It will be the responsibility of G.J. Oliver at which the

flow and temperature conditions for one (1) hour. operational test is conducted to provide all non-contract

Hammer pipe frequently. test instrumentation, utilities, power sources, etc.

13. Shut down pumps, remove and inspect screens. System necessary to comply with the contract test agenda.

and screens shall meet cleanliness requirements of API These items are to be installed and ready for test before

614 2nd Edition, sections 4.3.3.7.1 and 4.3.3.7.2. personnel are called for test witness.

14. If screens fail to pass the cleanliness test in step 13 then 10. The sequence of operational testing and specific

steps 11, 12 and 13 must be repeated until the screens comments relating to the individual tests shall be as

indicate acceptable dirt levels. Good judgment should follows:

be used in length of time used in step #11. a. Relief valve test e all relief valves on system shall be

15. Remove jumpers and inspect any components jumpered tested to demonstrate capability of relief at full flow

out during flush. Components must be cleaned and required by system design; set press/accumulation

preserved before putting them back in system. press record shall be documented.

16. Drain and clean reservoir, seal all openings and prepare b. Transfer valve test e all transfer valves on system shall

for shipment. be tested to demonstrate maintenance of flow through

17. Inspect filter interior, clean out any sludge or dirt in transfer function and for minimal/no leakage to shut-

filter casing and install contract elements. off side of valve. Test shall be done at normal supply

18. Inspect transfer valve intervals for dirt (plug must be conditions.

pulled). If dirty, clean and preserve prior to re-assembly. c. Running test e a running test shall be conducted for

a period of four (4) hours unless otherwise

II. specified. During the course of the test, periodic

checks shall be made to ensure stabilized conditions

A. Testing have been maintained within tolerances specified in

1. Cleanliness, hydrostatic and noise testing is not covered para. 5.

under this specification. 11. The maximum flow conditions test and transfer valve

2. The system is to be checked by QC for proper piping test must all be performed successfully with equipment

arrangements, component installation and identification adjustments in the same position. If minor adjustments

to ensure compliance with the systems diagram and bill of are made during any one of these tests, then any of the

material. four tests made prior to the adjustment must be

3. Component instruction manuals must be checked by test repeated using the new adjustment. If however, the

personnel to ensure proper adjustments, lubrication, etc. adjustments are known not to affect prior tests, then

4. All oil leaks shall be corrected before operational tests are prior test need not be repeated if approved by customer.

started. This does not include intended oil leakages as 12. The transfer valve test and running test shall be

from packed seals or minor seepage from seals on oil conducted with equipment and lines operating at

pumps. normal oil flow conditions.

5. All tests are to be conducted with pressures and flows set 13. All G.J.O. instrumentation that is used for testing

within þ/ 5% tolerance of the requirements. console shall be calibrated with date of calibration.

6. Oil having a viscosity of approximately 150 SSU and 14. Customers are to be notified at least 5e10 days prior to

100 F. shall be used unless otherwise specified. test schedule.

7. Oil temperature must be maintained at 110 to 120 F. 15. Data recorded for formal presentation shall be per the

During operational tests, if system is tested. ‘systems test data sheets for operational tests’, plus any

8. Contract switches which are mounted on consoles or additional data as required by the test agenda.

equipment (press/temp. and level) shall be demonstrated

to show set points and to be recorded.

405