Page 387 - Fundamentals of Gas Shale Reservoirs

P. 387

DEVELOPMENT PHASE DISCUSSION 367

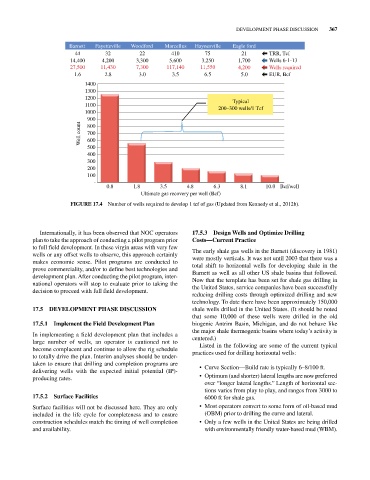

Barnett Fayetteville Woodford Marcellus Haynesville Eagle ford

44 32 22 410 75 21 TRR, Tcf

14,400 4,200 3,300 5,600 3,250 1,700 Wells 6-1-13

27,500 11,430 7,300 117,140 11,550 4,200 Wells required

1.6 2.8 3.0 3.5 6.5 5.0 EUR, Bcf

1400

1300

1200 Typical

1100 200–300 wells/1 Tcf

1000

900

Well count 700

800

600

500

400

300

200

100

-

0.8 1.8 3.5 4.8 6.3 8.1 10.0 Bcf/well

Ultimate gas recovery per well (Bcf)

FIGURE 17.4 Number of wells required to develop 1 tcf of gas (Updated from Kennedy et al., 2012b).

Internationally, it has been observed that NOC operators 17.5.3 Design Wells and Optimize Drilling

plan to take the approach of conducting a pilot program prior Costs—Current Practice

to full field development. In these virgin areas with very few The early shale gas wells in the Barnett (discovery in 1981)

wells or any offset wells to observe, this approach certainly were mostly verticals. It was not until 2003 that there was a

makes economic sense. Pilot programs are conducted to total shift to horizontal wells for developing shale in the

prove commerciality, and/or to define best technologies and Barnett as well as all other US shale basins that followed.

development plan. After conducting the pilot program, inter- Now that the template has been set for shale gas drilling in

national operators will stop to evaluate prior to taking the the United States, service companies have been successfully

decision to proceed with full field development.

reducing drilling costs through optimized drilling and new

technology. To date there have been approximately 150,000

17.5 DEVELOPMENT PHASE DISCUSSION shale wells drilled in the United States. (It should be noted

that some 10,000 of these wells were drilled in the old

17.5.1 Implement the Field Development Plan biogenic Antrim Basin, Michigan, and do not behave like

the major shale thermogenic basins where today’s activity is

In implementing a field development plan that includes a centered.)

large number of wells, an operator is cautioned not to Listed in the following are some of the current typical

become complacent and continue to allow the rig schedule practices used for drilling horizontal wells:

to totally drive the plan. Interim analyses should be under-

taken to ensure that drilling and completion programs are • Curve Section—Build rate is typically 6–8/100 ft.

delivering wells with the expected initial potential (IP)‐

producing rates. • Optimum (and shorter) lateral lengths are now preferred

over “longer lateral lengths.” Length of horizontal sec-

tions varies from play to play, and ranges from 3000 to

17.5.2 Surface Facilities 6000 ft for shale gas.

Surface facilities will not be discussed here. They are only • Most operators convert to some form of oil‐based mud

included in the life cycle for completeness and to ensure (OBM) prior to drilling the curve and lateral.

construction schedules match the timing of well completion • Only a few wells in the United States are being drilled

and availability. with environmentally friendly water‐based mud (WBM).