Page 174 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 174

Superconducting Magnet Systems Chapter | 5 155

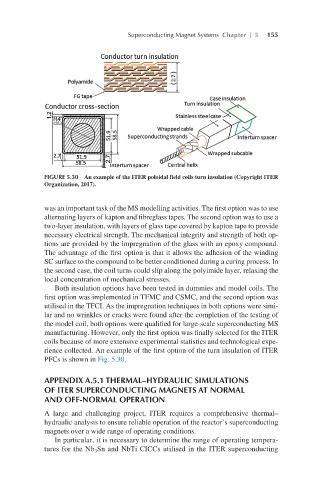

FIGURE 5.30 An example of the ITER poloidal field coils turn insulation (Copyright ITER

Organization, 2017).

was an important task of the MS modelling activities. The first option was to use

alternating layers of kapton and fibreglass tapes. The second option was to use a

two-layer insulation, with layers of glass tape covered by kapton tape to provide

necessary electrical strength. The mechanical integrity and strength of both op-

tions are provided by the impregnation of the glass with an epoxy compound.

The advantage of the first option is that it allows the adhesion of the winding

SC surface to the compound to be better conditioned during a curing process. In

the second case, the coil turns could slip along the polyimide layer, relaxing the

local concentration of mechanical stresses.

Both insulation options have been tested in dummies and model coils. The

first option was implemented in TFMC and CSMC, and the second option was

utilised in the TFCI. As the impregnation techniques in both options were simi-

lar and no wrinkles or cracks were found after the completion of the testing of

the model coil, both options were qualified for large-scale superconducting MS

manufacturing. However, only the first option was finally selected for the ITER

coils because of more extensive experimental statistics and technological expe-

rience collected. An example of the first option of the turn insulation of ITER

PFCs is shown in Fig. 5.30.

APPENDIX A.5.1 THERMAL–HYDRAULIC SIMULATIONS

OF ITER SUPERCONDUCTING MAGNETS AT NORMAL

AND OFF-NORMAL OPERATION

A large and challenging project, ITER requires a comprehensive thermal–

hydraulic analysis to ensure reliable operation of the reactor’s superconducting

magnets over a wide range of operating conditions.

In particular, it is necessary to determine the range of operating tempera-

tures for the Nb Sn and NbTi CICCs utilised in the ITER superconducting

3