Page 68 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 68

ITER – International Thermonuclear Experimental Reactor Chapter | 3 51

If these conditions are met, the CS parameters are far from optimum. Mechani-

cal stresses in the conduit material reach 375 MPa and remain heavy at cryo-

genic temperatures. The requirement for the CS case and load-bearing structure

material is, therefore, primarily a plastic high-strength steel. The material of

choice was the 316LN very low-carbon cold-worked steel.

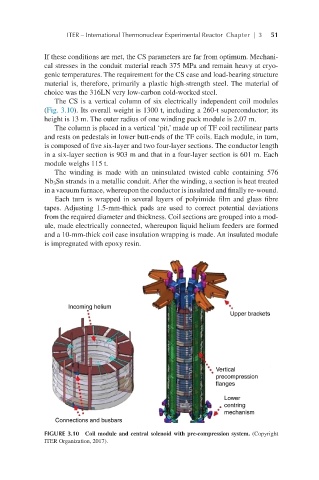

The CS is a vertical column of six electrically independent coil modules

(Fig. 3.10). Its overall weight is 1300 t, including a 260-t superconductor; its

height is 13 m. The outer radius of one winding pack module is 2.07 m.

The column is placed in a vertical ‘pit,’ made up of TF coil rectilinear parts

and rests on pedestals in lower butt-ends of the TF coils. Each module, in turn,

is composed of five six-layer and two four-layer sections. The conductor length

in a six-layer section is 903 m and that in a four-layer section is 601 m. Each

module weighs 115 t.

The winding is made with an uninsulated twisted cable containing 576

Nb Sn strands in a metallic conduit. After the winding, a section is heat treated

3

in a vacuum furnace, whereupon the conductor is insulated and finally re-wound.

Each turn is wrapped in several layers of polyimide film and glass fibre

tapes. Adjusting 1.5-mm-thick pads are used to correct potential deviations

from the required diameter and thickness. Coil sections are grouped into a mod-

ule, made electrically connected, whereupon liquid helium feeders are formed

and a 10-mm-thick coil case insulation wrapping is made. An insulated module

is impregnated with epoxy resin.

FIGURE 3.10 Coil module and central solenoid with pre-compression system. (Copyright

ITER Organization, 2017).