Page 70 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 70

ITER – International Thermonuclear Experimental Reactor Chapter | 3 53

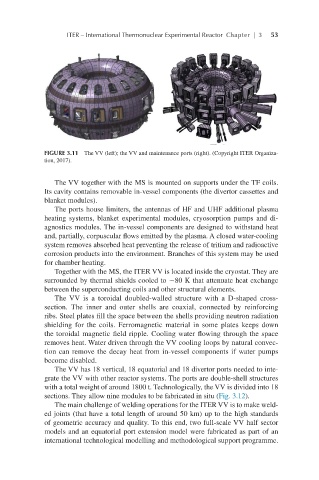

FIGURE 3.11 The VV (left); the VV and maintenance ports (right). (Copyright ITER Organiza-

tion, 2017).

The VV together with the MS is mounted on supports under the TF coils.

Its cavity contains removable in-vessel components (the divertor cassettes and

blanket modules).

The ports house limiters, the antennas of HF and UHF additional plasma

heating systems, blanket experimental modules, cryosorption pumps and di-

agnostics modules. The in-vessel components are designed to withstand heat

and, partially, corpuscular flows emitted by the plasma. A closed water-cooling

system removes absorbed heat preventing the release of tritium and radioactive

corrosion products into the environment. Branches of this system may be used

for chamber heating.

Together with the MS, the ITER VV is located inside the cryostat. They are

surrounded by thermal shields cooled to ∼80 K that attenuate heat exchange

between the superconducting coils and other structural elements.

The VV is a toroidal doubled-walled structure with a D-shaped cross-

section. The inner and outer shells are coaxial, connected by reinforcing

ribs. Steel plates fill the space between the shells providing neutron radiation

shielding for the coils. Ferromagnetic material in some plates keeps down

the toroidal magnetic field ripple. Cooling water flowing through the space

removes heat. Water driven through the VV cooling loops by natural convec-

tion can remove the decay heat from in-vessel components if water pumps

become disabled.

The VV has 18 vertical, 18 equatorial and 18 divertor ports needed to inte-

grate the VV with other reactor systems. The ports are double-shell structures

with a total weight of around 1800 t. Technologically, the VV is divided into 18

sections. They allow nine modules to be fabricated in situ (Fig. 3.12).

The main challenge of welding operations for the ITER VV is to make weld-

ed joints (that have a total length of around 50 km) up to the high standards

of geometric accuracy and quality. To this end, two full-scale VV half sector

models and an equatorial port extension model were fabricated as part of an

international technological modelling and methodological support programme.